|

Last weekend, adrenaline junkies and car enthusiasts gathered at the renowned Utah Motorsports Campus for an exhilarating roll racing event. The atmosphere was charged with excitement as participants showcased their high-performance machines and put their skills to the test. Among the impressive vehicles that stood out was our 98' Ram, which, despite running at a modest 8 psi, delivered an exceptional performance. As the sun bathed the track in golden hues, the Ram rumbled to life, revealing its beastly capabilities. Roll racing, a form of drag racing where participants start from a rolling position, would put the Ram's power and agility to the ultimate test. Despite its imposing size, the Ram boasted an upgraded 410ci engine and modifications to enhance its performance on the asphalt such as the 305 Mickey Thompson ET street tires. With the engines revving and the anticipation palpable, the weekend of roll racing kicked off. The Ram wasted no time in proving its worth, as it effortlessly sprinted down the straightaways, leaving a trail of awe-struck spectators in its wake. What truly made the Ram a standout was its ability to achieve an impressive performance with just 8 psi of boost pressure. While some competitors relied on much higher boost levels, the Ram demonstrated that it's not just about brute force but also the finesse of engineering. With its well-tuned engine and efficient power delivery, the Ram showcased that it's not always about the numbers but the overall package. Beyond the thrill of the races, the roll racing event fostered a strong sense of camaraderie among participants. Enthusiasts from various backgrounds came together to share their passion for motorsports and admire each other's vehicles. The Ram, with its striking presence and impressive performance, became a conversation starter, sparking discussions about modifications, horsepower, and the art of customization. The weekend at the Utah Motorsports Campus roll racing event was nothing short of exhilarating. The Ram, left a lasting impression on both the crowd and fellow participants. It served as a testament to the engineering prowess and dedication of our business, showcasing that true performance is not always defined by raw horsepower alone. As the event came to a close, the memories of roaring engines, adrenaline-fueled races, and the camaraderie of like-minded enthusiasts lingered in the air. The Utah Motorsports Campus once again proved to be a haven for speed enthusiasts and a place where dreams of power and performance come to life. Until the next gathering, we eagerly await the next opportunity to witness the awe-inspiring feats of these incredible machines. The current 220/220 108 lsa camshaft bleeds off boost from the Procharger, but a new camshaft from Performance Injection Equipment will be arriving based on my specs from testing years ago. The new profile is 236/242 114 lsa and .525 lift. I will also be upgrading the in-tank fuel pump to a 450lph plus other belt modifications in preparations for August and October roll racing. Stay tuned!! https://www.youtube.com/channel/UC6dy_nHXqkiVHFdik6Gjo4A

4 Comments

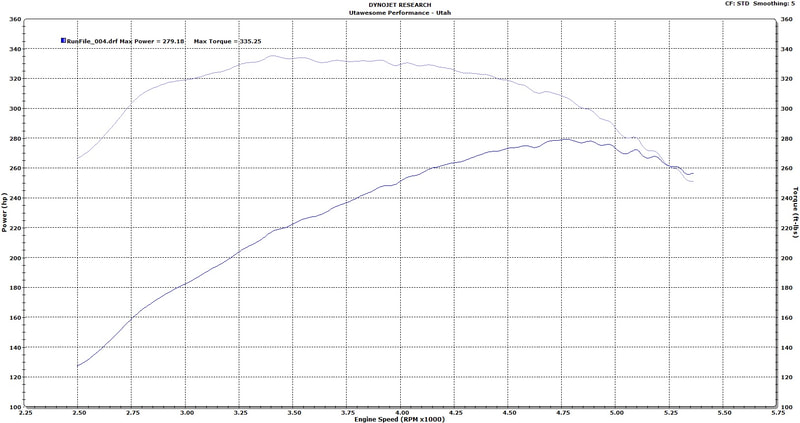

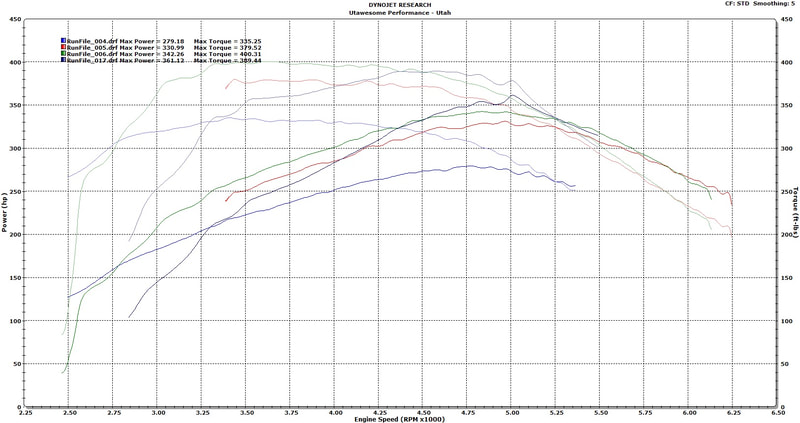

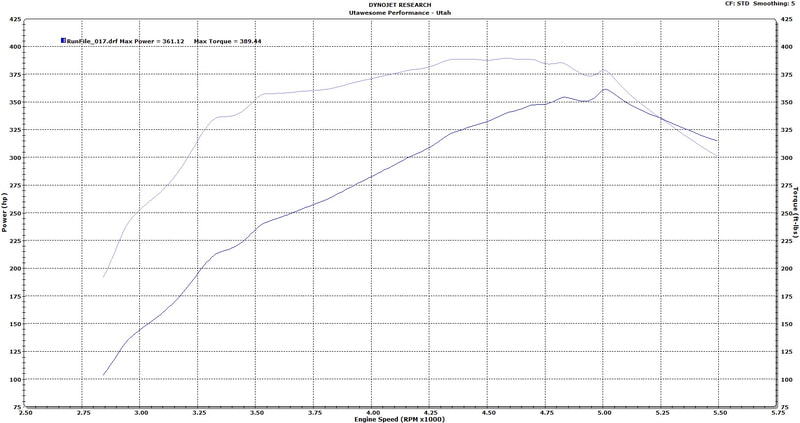

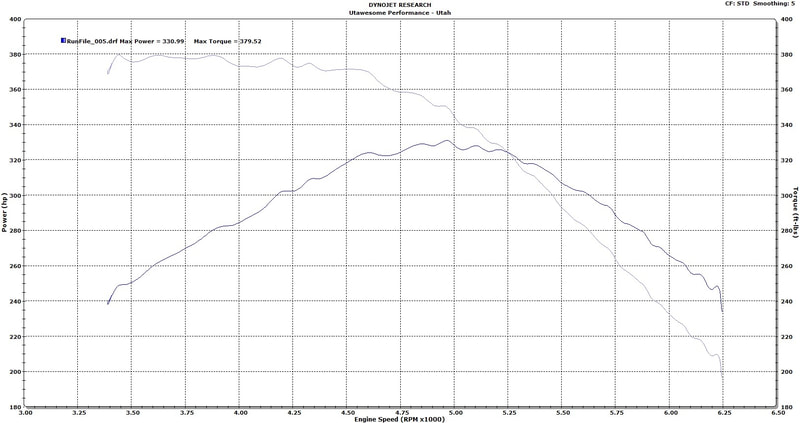

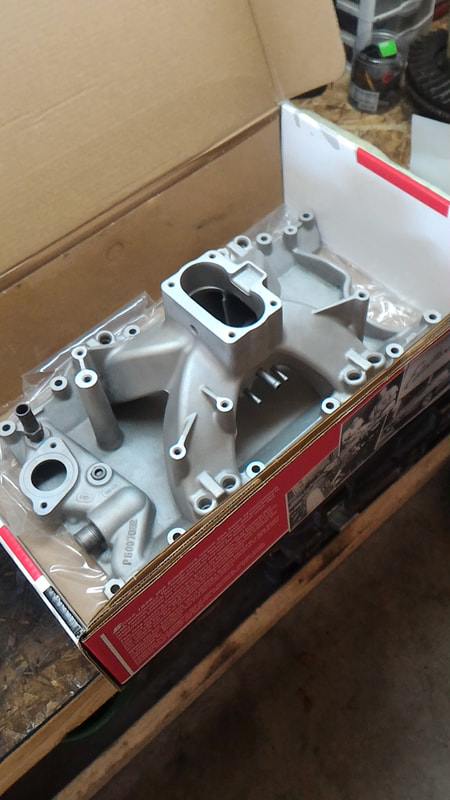

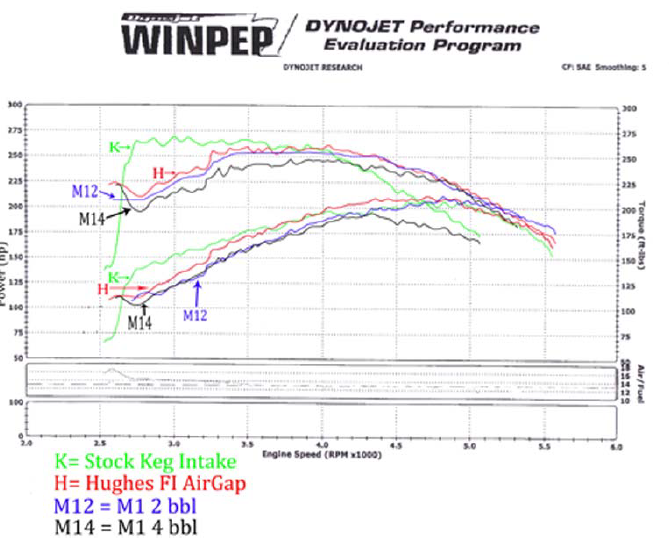

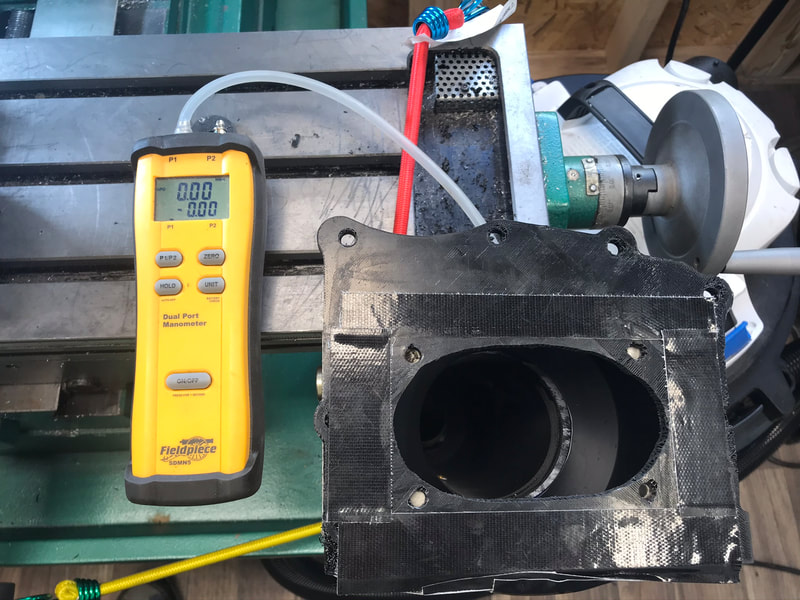

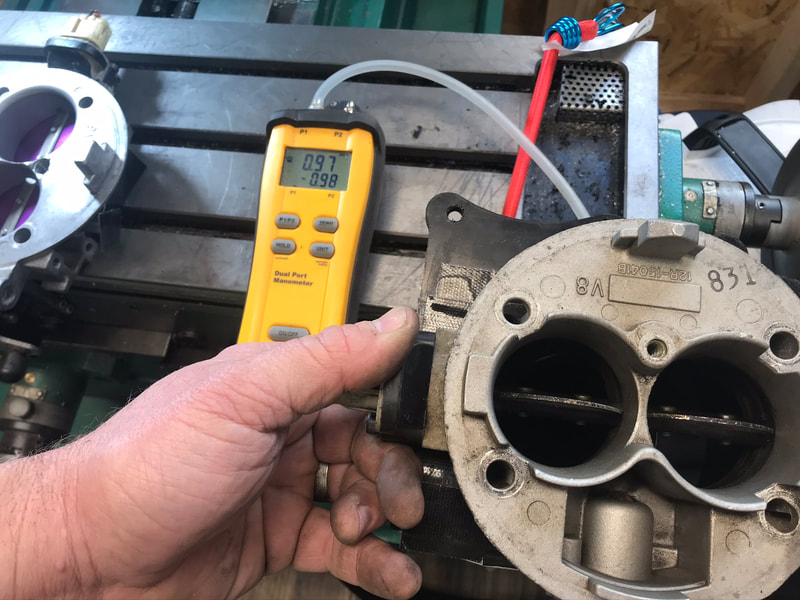

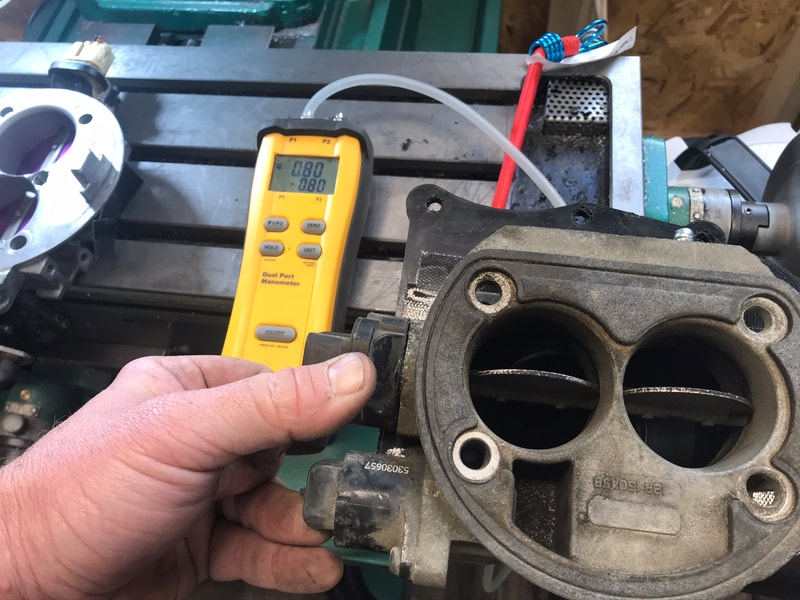

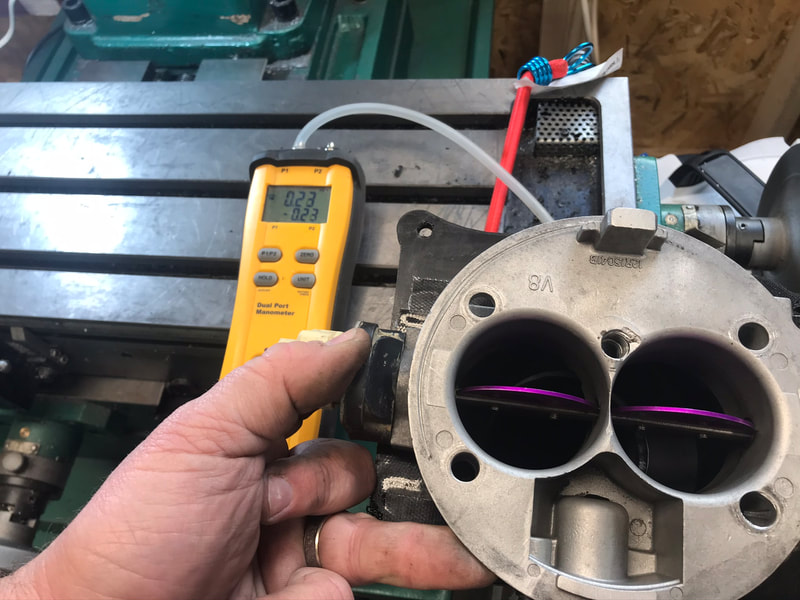

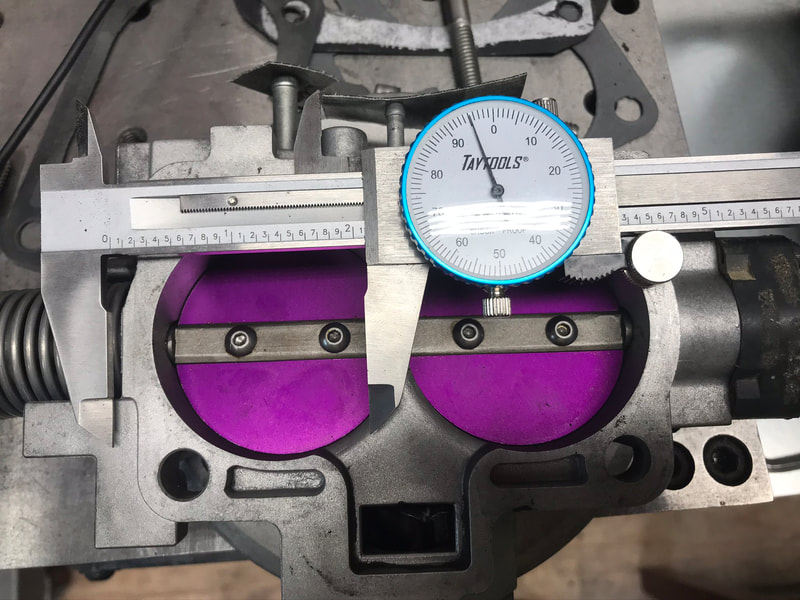

As promised, the manifold testing of 4 different manifold is finally complete. There is a fifth manifold that gave me much trouble on the dyno as you will see.

The Manifolds are as follows-

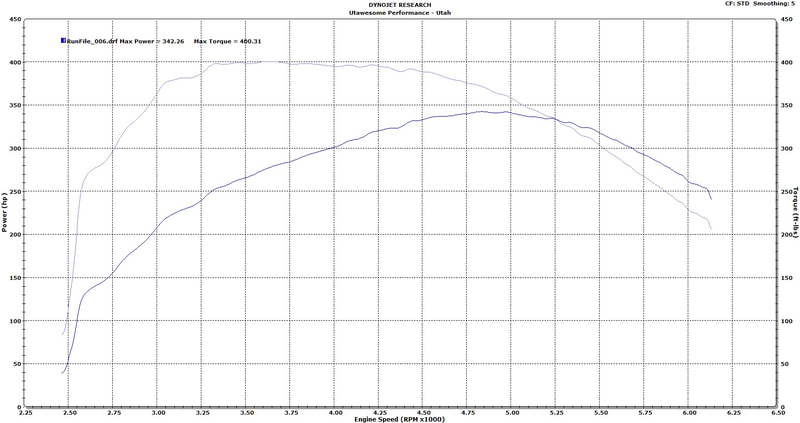

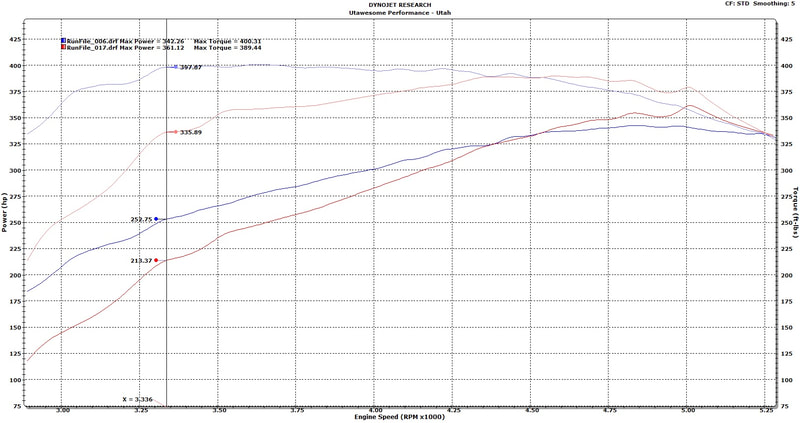

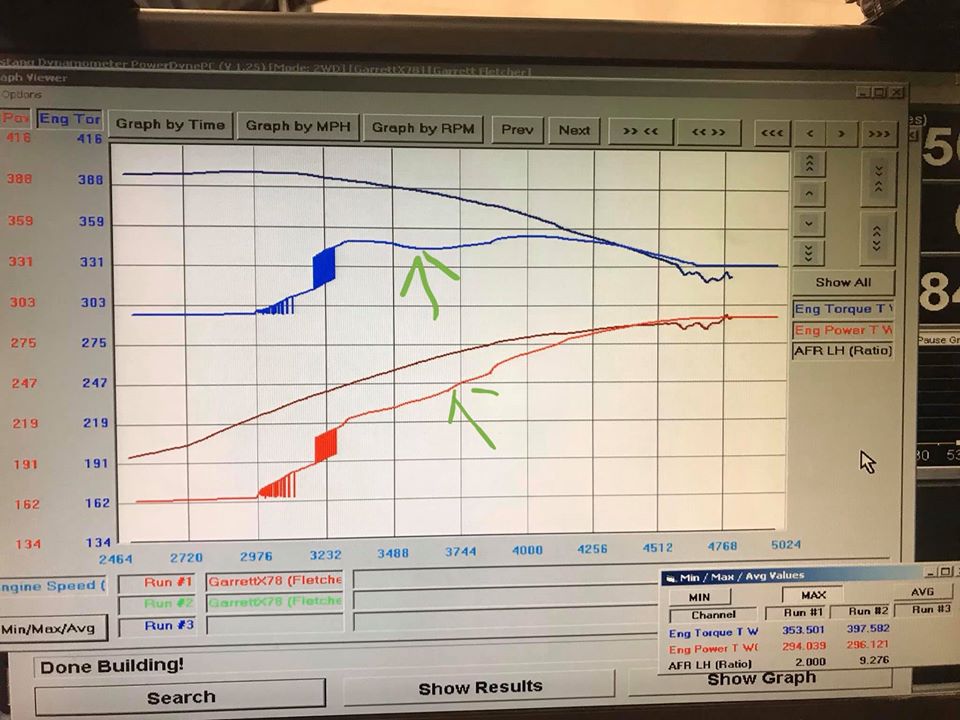

The 6 pack manifold had issues with my linkage and wasted my time on the dyno chasing that issue. Running out of time, I removed it and installed the M1 2bbl for the final testing. The baseline is a 1998 Ram, 408ci, 10.3 compression, Stage 1 PIE EQ heads, UTP 220X camshaft, longtubes and tuned by the SCT. Which brings me to my next issue. The Syked tuner was doing well until the software updated automatically and being out of business, it would no longer run. I had to switch a new SCT back on to start the testing a day late than when I had scheduled. As expected the stock kegger choked the 408ci by 51hp and 47 tq. Once the M1 was installed the peak torque jumped from 3300 to 4500. The HP feels great on the top end, but driving it shows a bottom end loss that next months dyno will surely make up for. Keep in mind, this is a 408ci, so a 360 or 318 will be less than these numbers but ramped the same.

As we close out this year I want to take the time to thank everyone for supporting our tiny shop. To all the customers and guys at Engine Masters, thank you for making this business an enjoyable one. I do not deal with large overhead, huge inventories and employees to care for. It is just Sharon and I working the shop and shipping the packages. Savannah is a full time mom now, so it is usually just my son Garrett with his SRT4 and myself working in the shop. My career in the past 7 years as kept me on the road so much, I did not have time to play in the shop as much as I really wanted. The intake manifold porting and throttle body work placed priority over my testing. So projects such as the roots blower and my GSXR1100 sand quad get pushed back. I would log in remotely all over the US to send tunes out. Now, huge thanks to my new local military engineering career, I get to be home every night and weekend! I am really looking forward to this next year.

With that said, I am working a dyno test up for our 408ci in the Ram. I have the dyno scheduled for a day, plenty of intake manifold gaskets and will be doing a same day back to back dyno of the following intake manifolds in this order:

I think you will all enjoy this too. Watch for this video in late January. cAMSHAFTS Last year was an odd year for anyone involved in the shipping industry worldwide. Being that I have been dyno testing and grinding camshafts through Comp Cams for 20+ years, I have come accustomed to the standard 8-10 business days grinding my patterns. The cost of hydraulic rollers settled down around $350 range with a meager profit line. It was more fun to sell a cam, chain, tuner, heads all together and see the results of a customers weekend efforts! But the economy has changed that. Custom grinds have been averaging $400 plus. Some are even in the 5 to 6 week grind times. Since September of last year, we have not had any cores to grind at Comp, I sold some of the very last cores. The suppliers are not getting the cores to Comp and other grinders. They continually move the dates out further and further. So, in March I was excited to be able to get cores at Comp but the drawback was that I could not grind any tighter LSA than a 110. Everyone knows I have studied Dave Vizard's work. His books are a great wealth of information. He found that the best torque you can get from a cam profile was the 108 lsa. So, even in my old 2000-2010 KRC Performance days, The little 210/220 108lsa was an excellent performer (the old 210X). The only drawback was the overlap that dumped raw fuel unburnt. The 108 has never been good for fuel economy. But for high peak torque matched to a intake runner length, it was wonderful. For the past '6' years I have been selling the UTP 450 cam profile. It is an excellent ramp profile, low lift for stock valve train, single pattern for high torque that has seen 360 rw all motor with the same combo. When you start testing different profiles, you must be careful. If you want the same results each time, then you need to stay with one profile and continue to improve all other areas such as intake and exhaust to maximize the results. That is what I have done with the UTP350, 450 and 500. When you can do this, you can ensure your customers results will be darn near close to the specs I drive everyday on the dyno in Sandy Utah.

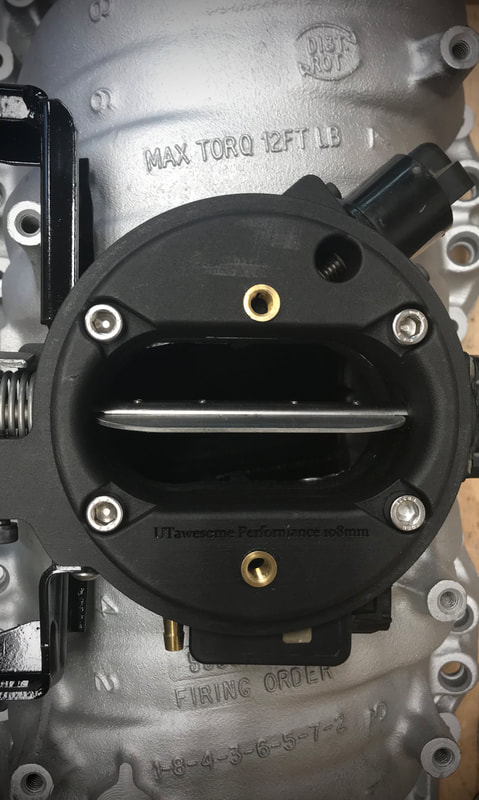

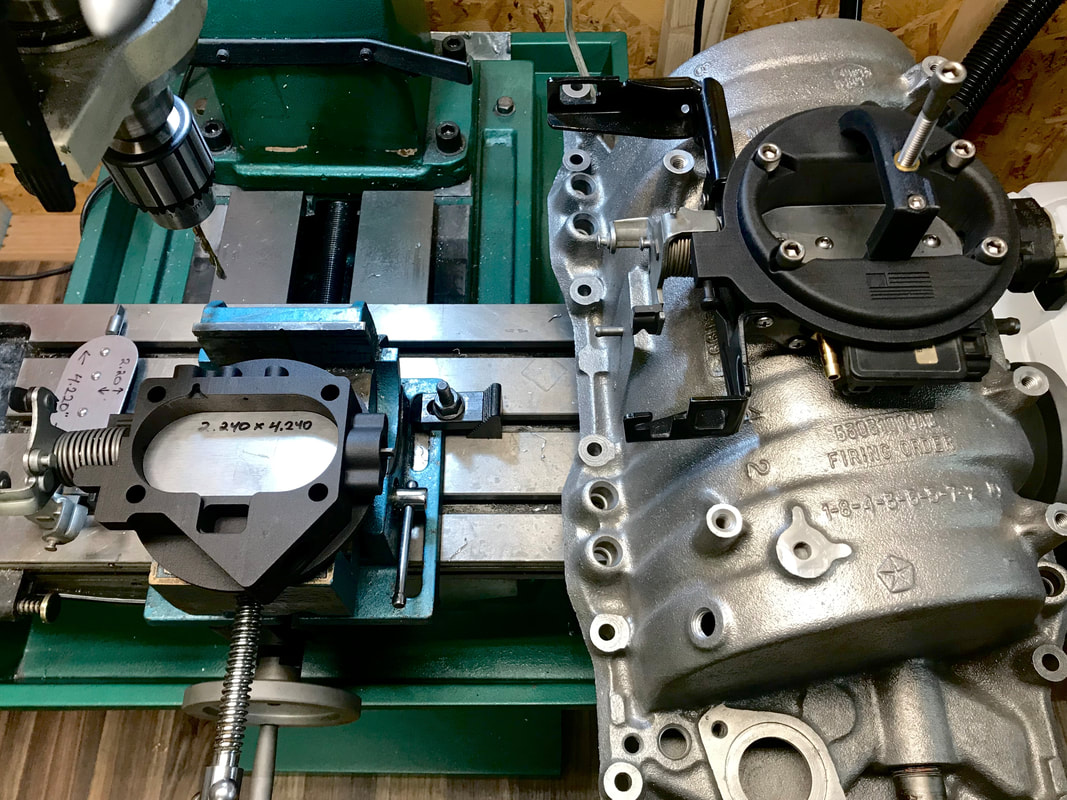

With the shipping issues of cores, you can see that it 'inserts' an untested variable into an already winning cookie cutter combination. That is where I do not want to be. I have spent thousands on dyno runs and intake manifold gaskets dialing it in. So my decision this month to no longer sell camshafts pushes that burden onto other cam sellers. It is not that I want to do that, I refer any cam grinding to Chris at Performance Injection Equipment (PIE), it's that I no longer want the hassle. I have plenty of work and satisfaction making the 108mm throttle bodies and porting the different intake manifolds. But to sell a cam for $500+ and tell the customer sorry, 3 to 4 weeks to grind and it's not really the specs I have tested, is no longer an option for us. So, that prompted me to remove the camshafts and chains from the online store. I have simply been forwarding cam emails from my customers to Chris at PIE. I am not going to hide the truth either, Comp directly raised the prices on everyone and we did not find out until balancing the books a month later, that we paid you guys to order camshafts. That right, my cams were costing us much more from Comp. If I were able to sell a camshaft in my tested profile, not the untested '110 lsa', then the price would now need to be $529 shipped. So after 22 years, I closed my account after discussions with my Comp representative. No need to get into the details, but just know, I am not happy with how it was handled- coming from this guy who everyone knows has been a die hard Comp Cams supporter for decades. I will be posting up a cam grind detail page for those who want to approach cam grinders to copy my tested specifications. It will be in the online store but no pricing. Use the information for what it is and take the specs to your cam grinder of choice. As for this months updates, I am getting the twin 52mm 3d printed ready to sell, plus the stage 2 shorter wedge for more horsepower in the kegger intake manifolds. Check out the latest video on YouTube concerning tips on reducing spark knock also. Take care and have a great month everyone! Since YouTube has copyright issues with me commenting on the Engine Masters episode, here is the link for the video. Password is UTP.

https://www.dailymotion.com/video/x8cn7g1

Welcome to the September update from Utawesome Performance. I would like to first start by offering condolences to Robert Taylor's family. He ran the Dodge Ram Sec Gen page for a very long time. He recently passed away and will be missed. He was always there supporting my work and overall shenanigans at the dyno shop. God Speed my friend.

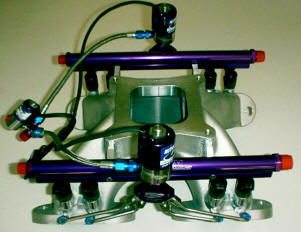

The roots supercharger design on the Ram 360 is coming along. The intake, blower and hidden intercooler are completed. Now I am working on machining my billet fuel rails (stock option in the works too) and the new designed 108mm throttle body to feed it. I can assure you all my dyno's next year will be with it. So for the longest time, I have campaigned the 10.3 compression all motor 360ci in Garrett's truck. Since he left on deployment to my old base in Afghanistan, Savannah and I have been working diligently to finish the last piece of the combo. It's no secret that this 360ci has been running stock untouched, cracked 1.92" Magnum heads since the build beginning. The entire reason for designing the UTP450 cam and the UTP500 cam was to use all stock parts and still have max power. I even performed a test and changed the lift on the UTP500 from 0.456" lift to 0.512" on the stock heads. As to be expected, I gained nothing on that dyno run. The stock heads are done at 0.450" lift (210-215 cfm). But still posting a super respectable 336rw and 403 tq on the ported kegger and a huge 108mm throttle body, the need for better heads is going to be the last test before next years massive supercharger work shift takes over. Chris at Performance Injection Equipment sent us an excellent set of his 2.02" iron CNC ported heads. The last time he sent us a set of hand worked heads for Savannah's Ram, we moved from 250rw to 275 rw. It will be exciting to see what the gains will be on the 10.3 engine. I will perform a mild cleanup on the ported kegger (matched to the heads), print a fresh throttle body out, 1121G thin head gaskets again and finally stepping away from the stock rockers we have beat on for so long and install a set of 1.6 roller rockers. Same 36lb injectors and still a stock torque converter. That will be the next fun piece adding a 2800 full lockup convertor. Some of you may remember from Facebook the super slow burnout with the old 318 that Savannah edited to have a sloth running next to. That truck has come a long way. So stay tuned and subscribe to our Youtube channel while the world is still calm! May has introduced some changes. First, when I deployed to Kandahar Afghanistan in 2010, I resisted the norm to have a Facebook account. But at the time, finding it was so easy to message the family, I started one. I enjoyed much of the photography while I was deployed and my live videos hiking in the US. I also enjoyed Rolf Sheffey's Facebook group 5.2 and 5.9l magnum engines. That group was given much insight to my builds and ideas. The messenger was simply becoming overloaded. Every few hours I would have 20-30 messages that required detailed answers that I could no longer keep up with. On top of that I was answering another 20-30 on my tech email. So instead of being censored by FB for loving God, Guns, Trucks and Black Rifle Coffee, I deleted the account. The video issues with the website are now corrected! I created a small Youtube website and uploaded the majority of all the past Facebook videos from the 5.9 forum. So they are sprinkled on the site here and stream perfect. Here is the May 2020 video update from my mancave of freedom! I am getting many emails on the latest debate concerning a stock intake reworked over the stock Hughes Airgap.

|

Marty FletcherHands on engine builder and tuner for Dodge since 1993. Archives

July 2023

Categories |