|

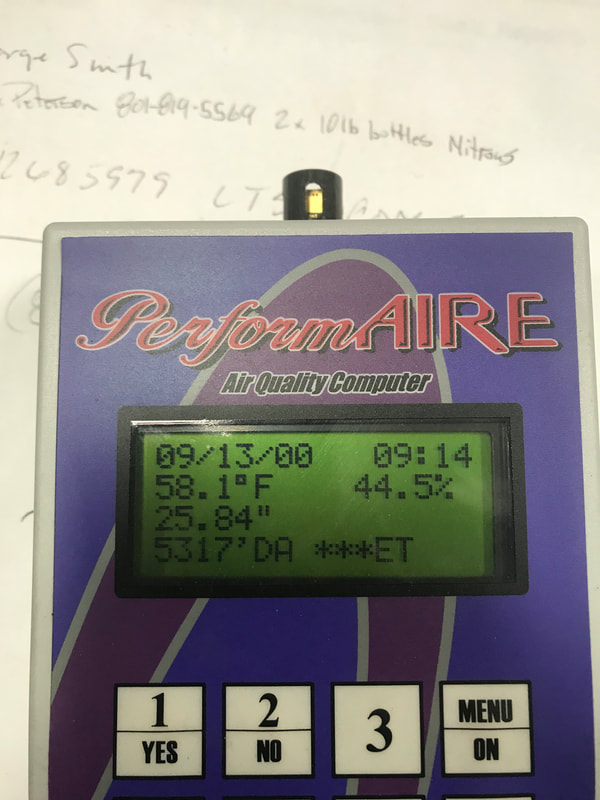

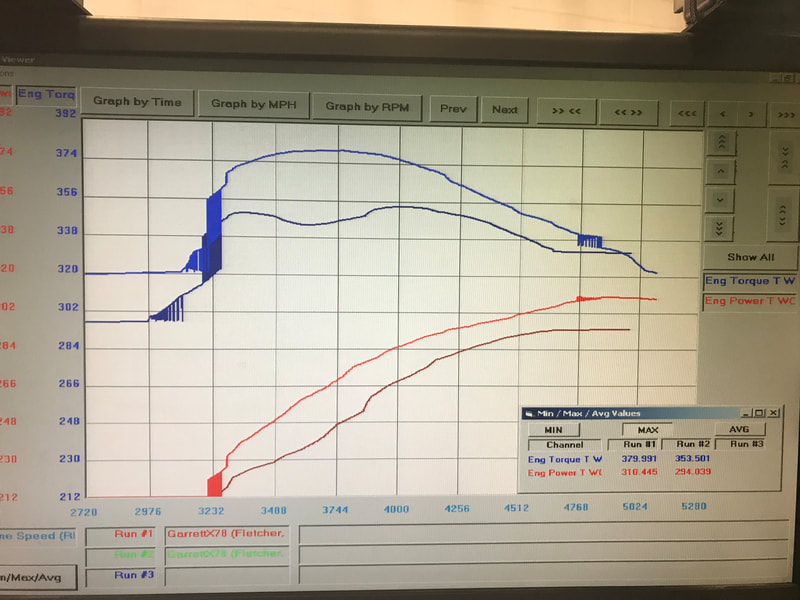

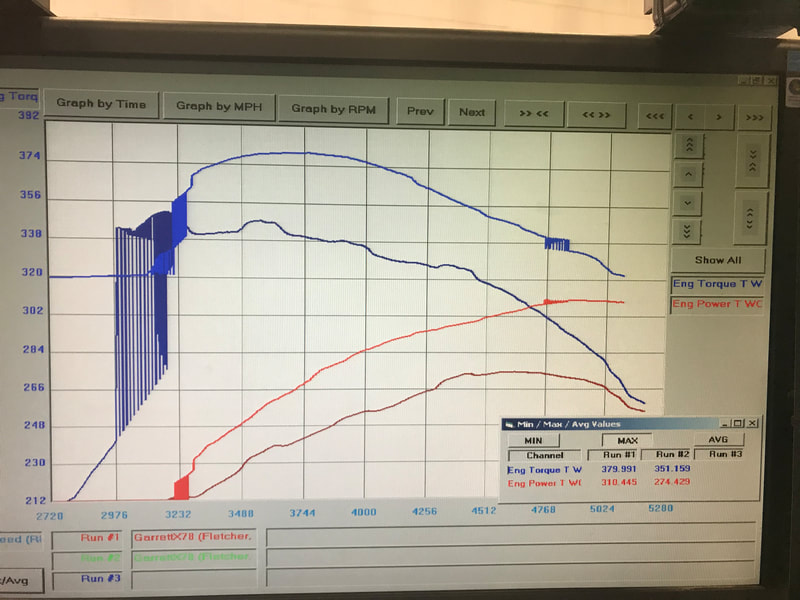

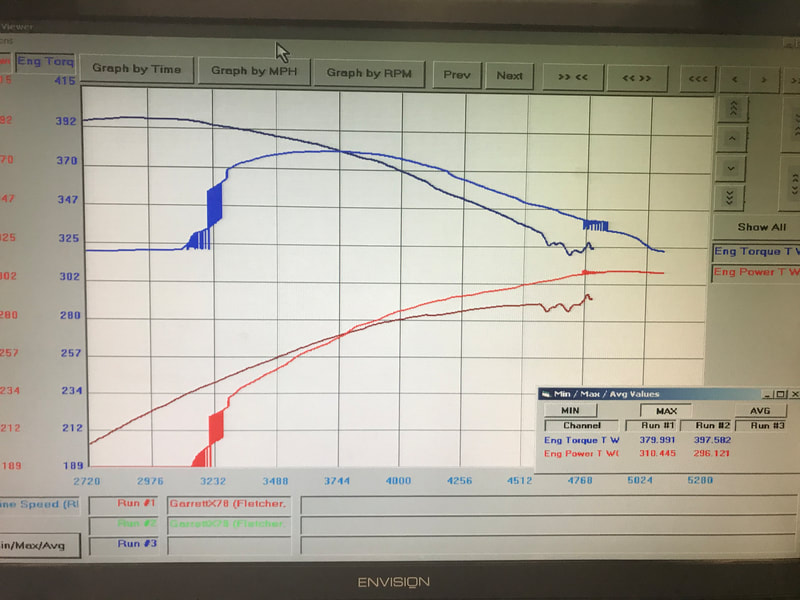

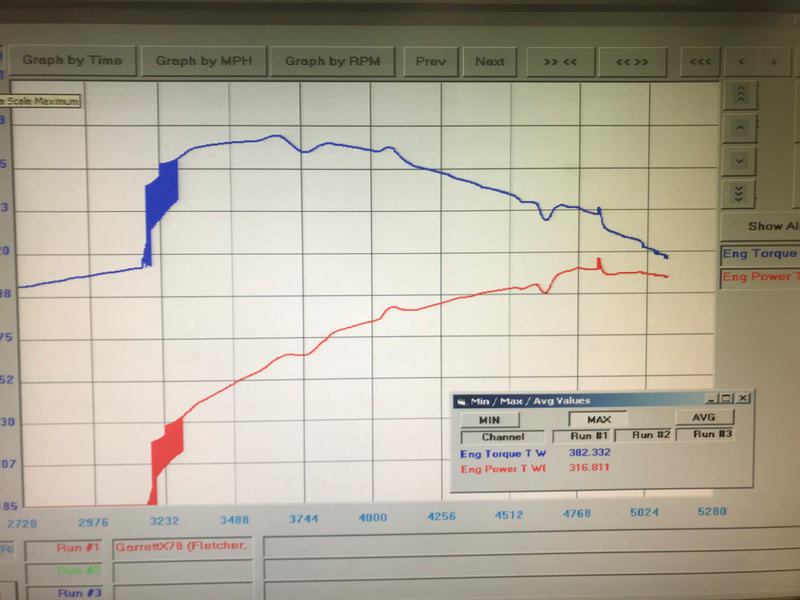

In the past year, the limits of the stock intake and heads in stock form have been built upon. First, after much flowbench work on the stock Magnum heads, we determined the max cfm at a specific lift. Using that 210 cfm number, I knew the horsepower potential the engine was capable of, using a long 18" runner. So work started on a single profile camshaft lobe that was not too aggressive that could be used on stock heads. That is where the UTP450 was born. Mild ramp on the roller lobes for the stock springs to benefit from and lift no higher than 0.456 to stay far away from bind. The head flow maxed out at 0.450 anyhow. With that design, the only item needed was a tune using the SCT or Syked (now HP also) and a tighter timing chain set ensuring no timing events were straying from where it was installed. Using the kegger intake un-modified, the rewards were great. The combo really made 450 tq and laid down a solid 350 tq at the tires. This was for driving, max peak torque at 3000 rpm, not 4500 as in the short runner intakes that are out there. The next hurdle was the low 170-180 cfm flow of the stock intake manifold. Somewhere in the mix of tearing them apart, I could not help but see the huge 6000cc's of plenum volume and wonder if the velocity could be sped up to the runners. That is when the CNC machine birthed the Volume Reducing Plates known as VRPs. What an outstanding gamble on the test trucks that turned out to be. From 1500 rpm to 3000 rpm, the tq responded much greater than the open plenum. Add a CNC heat shield that started life from a big block 383 valley pan, reducing the heat on the intake allowed me to run lower octane fuels on better spark advance curves. In the end with stock heads, the big Ram on 37s pulled off 240+ rw and 350 tq. That is where the next test Ram running a 10.8 compression 360 came into testing. The UTP500 cam changed from the 215 duration to the 220. Running the same mods and dyno testing at 5000 feet, the truck made 290+hp and 370+ tq. At sea level it really enjoyed the extra 30% oxygen and made 336hp and 403 tq! So it was time to rethink the port flow on the stock intake. Long reach bits and port matching the runners to the intake side of the stock heads was next. After many hours, 24 total of shaping and grinding, the CSA was opened up to a nice 2.28". In the time of that work, a good friend sent me his Hughes Airgap to test on the dyno. Power was 290+ but had dropped to 350+ in torque. Now one could bump the stall convertor and steepen the rear gears to enjoy that, but the peak tq once again was all the way at 4500 rpm. Nowhere near where my daily driving was at. With the stock kegger opened up 14% the dyno was again rolling. But I did not make it to the dyno without making a taboo mistake. I changed the camshaft profile. The stock heads only had a valve spring upgrade, the standard Mopar Performance 062 springs. With that, I needed a camshaft profile that would take advantage of the EQ and Edelbrock flow cfm numbers at 0.500" lift. Well above the stock Magnums. Choosing the Extreme Energy lobes, the only thing that changed was the lift. From 0.456" to 0.507". Would the Magnum heads that make no more cfm at 0.450" of lift produce anymore power on this aggressive roller ramp profile? Would I exceed my best torque numbers of 400 up at 5000 feet? Well, no. While peak numbers are good for selling, the better way to weed through the info is the average gains. The new camshaft was dialed in for a flat 12.8 afr with 34 degrees of total timing and posted 310 hp and 379 tq. Before was 296hp and 397 tq. SO a few things to consider are- first, the heads make no more cfm at 0.450 lift and pushing that slowed the cylinder fill velocity. Number two- the intake port CSA is too large for the stock Magnum head. But the good part is that from 3800 rpm, both HP and TQ where 15-20 higher to 5200 rpm. That explains why the truck pulled so well on the street from 3500 on. So that brings us to the next test, better heads. Either Performance Injection Equipment will setup Engine Quest 2.02 heads or I will splurge for 2.08 Eddy heads prepped by them. I am certain that the current large CSA manifold is not a restriction to them. Also in the works is testing a larger oval throttle body I am machining into place. Now none of this is to say the stock intake is the best, it certainly is not. A whole new intake design needs to be cast with an adjustable runner such as the LSX. For race applications, the shorter 4" runner would be used and for heavy street/ 4x4 the longer 16" would be used. That would be optimal. Maybe we will see that. But till then, I will keep nickle and diming' the combo for the best torque output, because everyone has heard me quote this: Build for torque, and your horsepower numbers will fall into place... Here are the dynos and work completed.

2 Comments

|

Marty FletcherHands on engine builder and tuner for Dodge since 1993. Archives

July 2023

Categories |