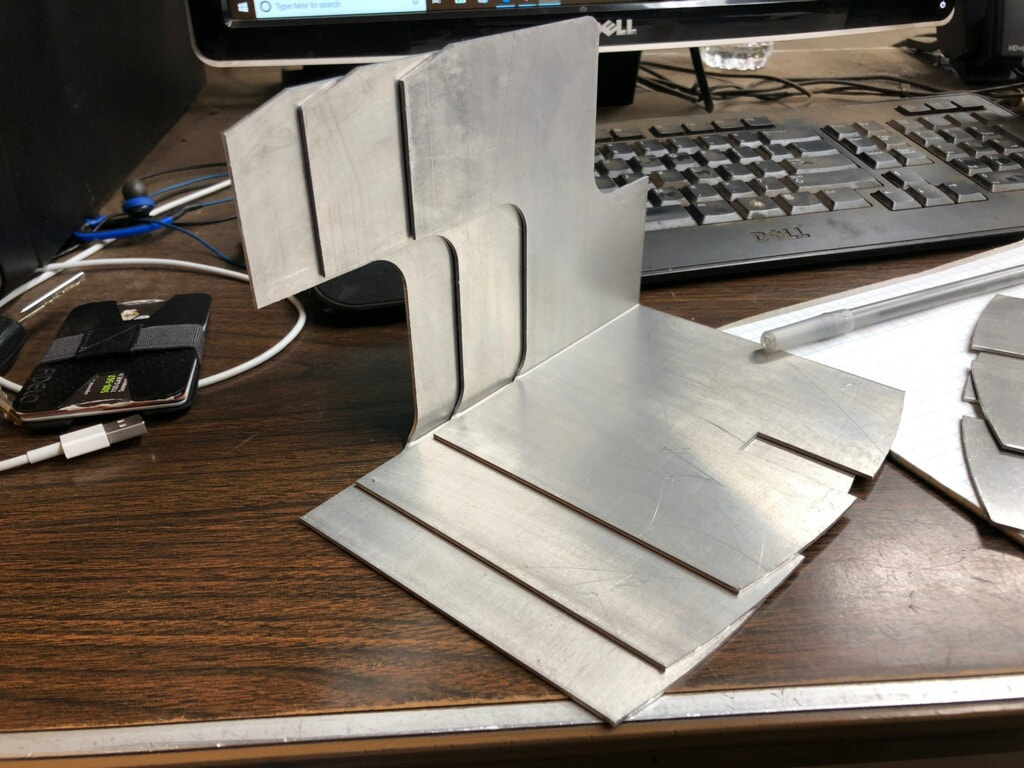

Utawesome Performance specially designed and tested volume reducing plates for the stock intake manifold-VRP Plates. The addition of these CNC 16 gauge aluminum plates reduces the massive volume in the kegger manifold and greatly increases the velocity of the incoming air. This is no quick install throttle body spacer gimmick, this is the real deal. It requires WORK. It changes the intake runner length and lengthens it while speeding up the incoming airflow. It's no secret stock eliminator Magnum 360's have been making 500+ foot pounds of torque on motor alone. Stock eliminator requires stock intake, throttle body and heads. They can only use a factory lift proprietary camshaft. For years, everyone has run the Mopar Performance M-1 in the 2bbl and 4bbl version. The Edelbrock AirGap has even been modified to run factory fuel injection with outstanding results. But at the end of the day, you simply lose torque from idle to 3000 rpm. Most have peak torque rpm at 4000 and higher. Long intake runners with proper sizing make the best of both worlds. You will not see a new Corvette or Hemi running a short runner manifold. The tuned runners are long and designed to maximize torque. The average CFM of magnum heads at 0.450 lift are 210-215cfm at 28". The factory intake manifold delivers 175-185 cfm but slowly. The Magnum was not initially intended for racing or high power as it was a truck motor. Further working of the factory intake manifold to the runners will exceed the head cfm requirement. Now, if your heads flow 215 cfm, simply bolting on a intake manifold that flows 300 cfm does not keep the velocity high. Keeping your port CFM in the intake manifold closer above the max CFM you will be using in the heads, is desired on a longer runner. Tapering is also a plus on the inlets, but we can get into that later. For now, lets get to the testing of these plates before and after their installation inside the kegger.

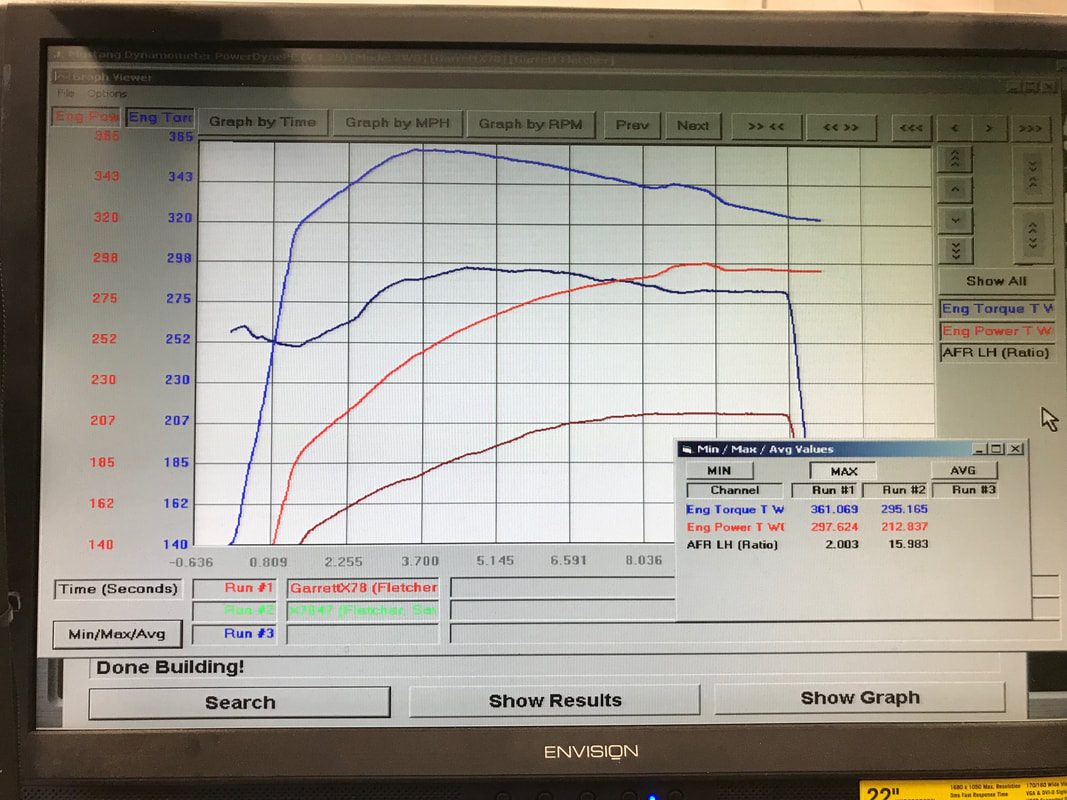

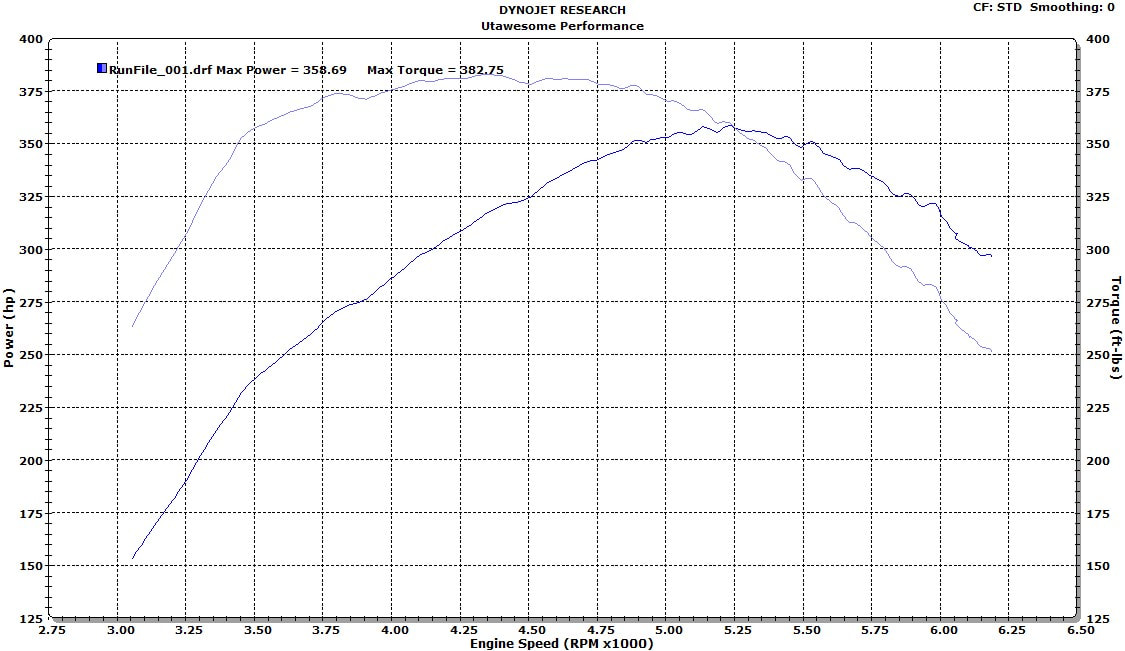

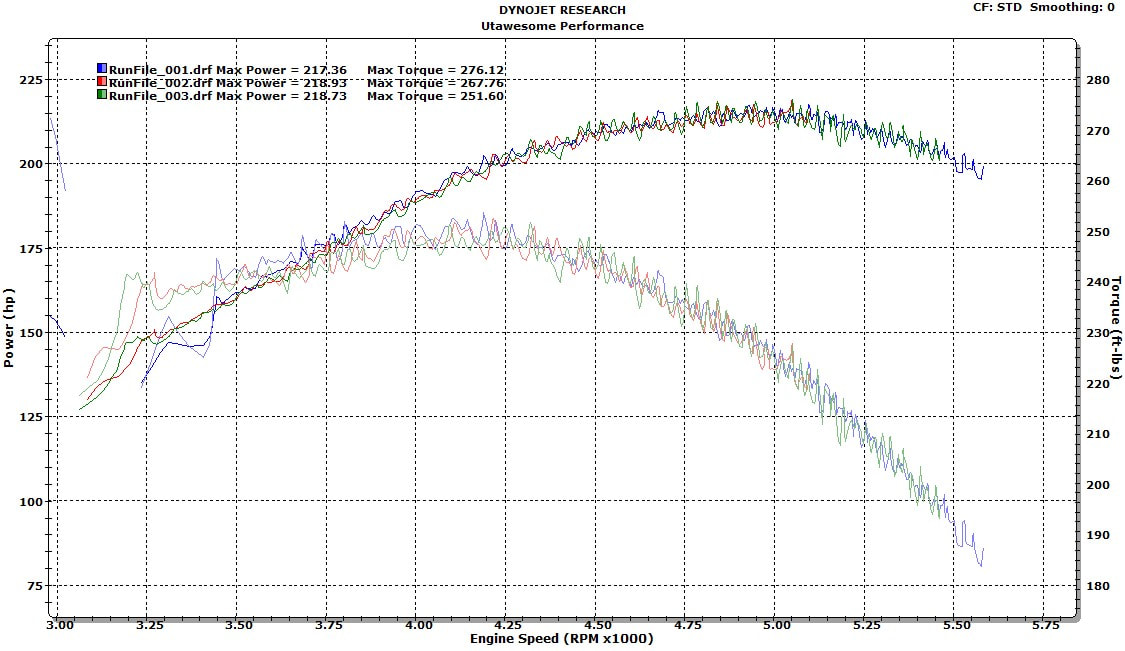

Our baseline dyno is a stout rebuilt 360 in a 98 SLT Ram. It is a 0.030 overbore stock piston that has been zero decked using a stock rods and 3.58" crank. The heads are stock 1.92 Magnum heads with only the valvesprings changed. The heads are and have been cracked across the valve seat. The camshaft is the UTP450X camshaft, Comp Timing set, DNA Longtube headers with a Magnaflow exhaust. The tuning is the standard SCT X3. Underneath the intake manifold is a heat splash shield to lower the intake manifold core temp on the plenum pan. Testing was done with a Kegger Stock, a 239cfm ported 18" runner without the plates and a untouched stock 18" runner kegger with the plates installed.

From a stock baseline 360, you can see the UTP450X cam and stock intake made 297 horsepower rear wheel and 361 torque. So then a ported 18" Runner was installed without the VRP Plates.

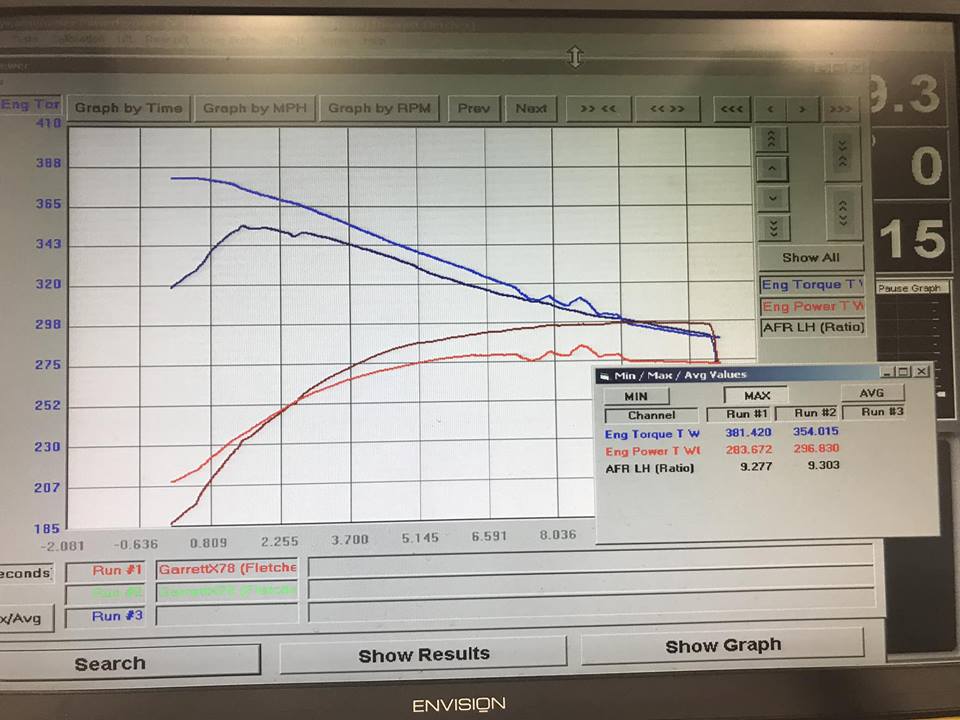

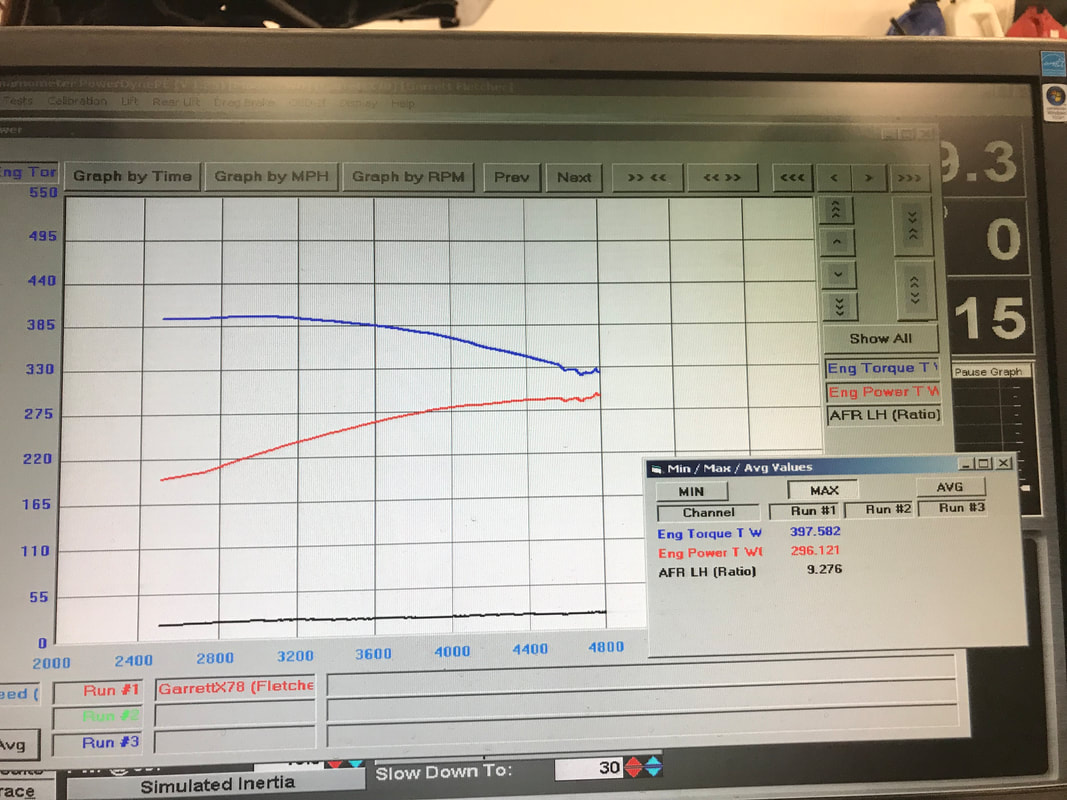

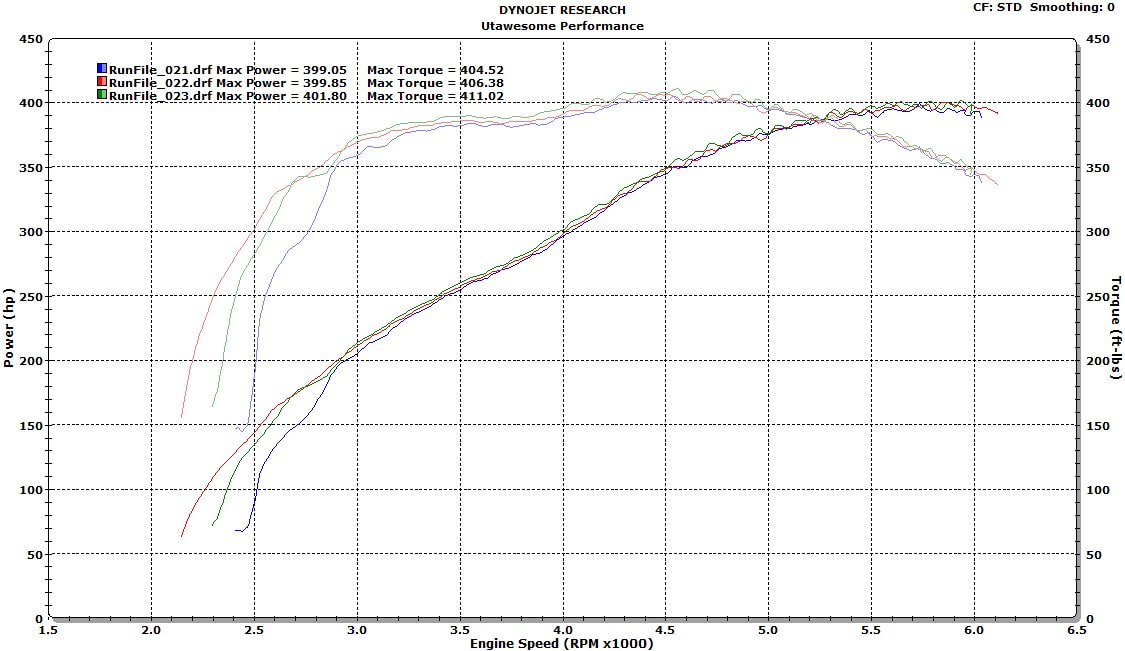

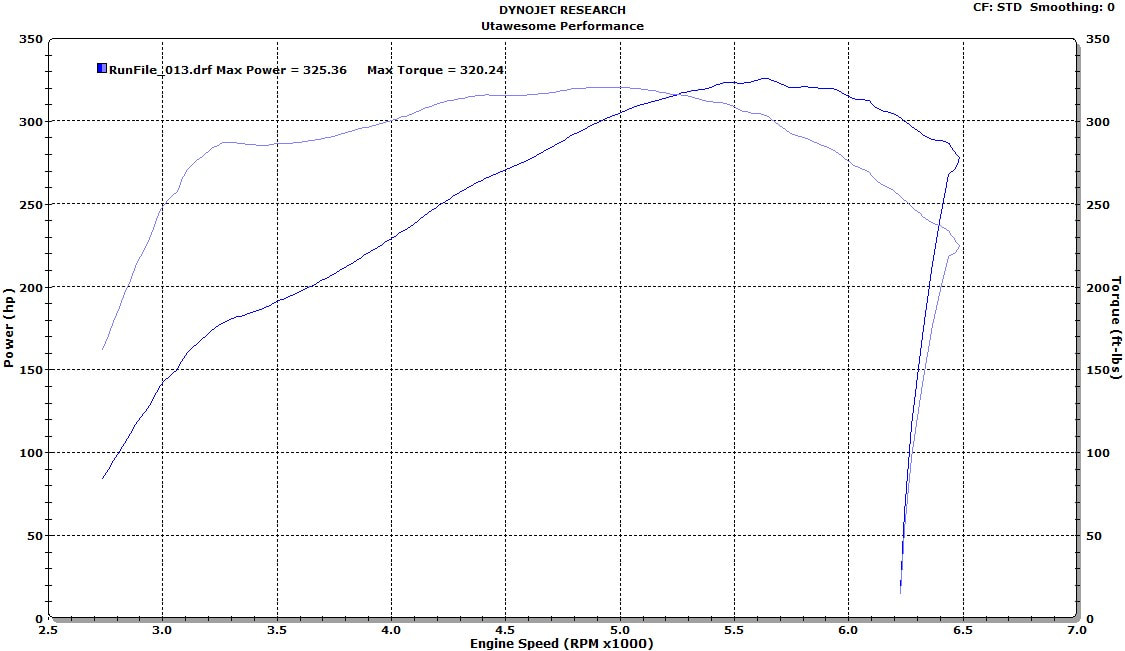

As you can see, the ported 18" Runner really made no difference by itself. It logged in at 296 horsepower and 354 torque. So what that told us was that my head CFM was maxed out. At 0.450" of lift my stock cracked Magnum heads flowed 176-178 CFM @ 20". Our flowbench up here at 5000 feet in altitude will not pull 28" as most sea level shops use. So to convert, you simply multiply your number by 1.180. In this case my heads flowed 210 cfm @28". That puts my portwork at 239 cfm. A nice slight gain above what the heads can pull. The next dyno is the VRP plates installed in a stock 18" runner that has not been ported and you can see that even with the runners only flowing 175 cfm, the increase in velocity was amazing. Throttle response was much quicker and the camshaft that was pulling 9" of vac at idle was now seeing 10-11" The first pull seen above was 283 horsepower and 381 foot lbs of torque. almost 30 foot lbs of torque at the rear tires on a non ported VRP Kegger. Simply letting the engine cool down from the dyno testing on the Mustang Dyno moved it up even further.

296 rear wheel horsepower and 397 foot lbs of torque on a relatively small profile street camshaft. The measured numbers that day showed even higher than that with 404 torque, but for the graph, we will take it! Currently I am installing VRP plates in my ported 18" 239 cfm kegger and will head back to the dyno to see what gains on a smooth large port will show.

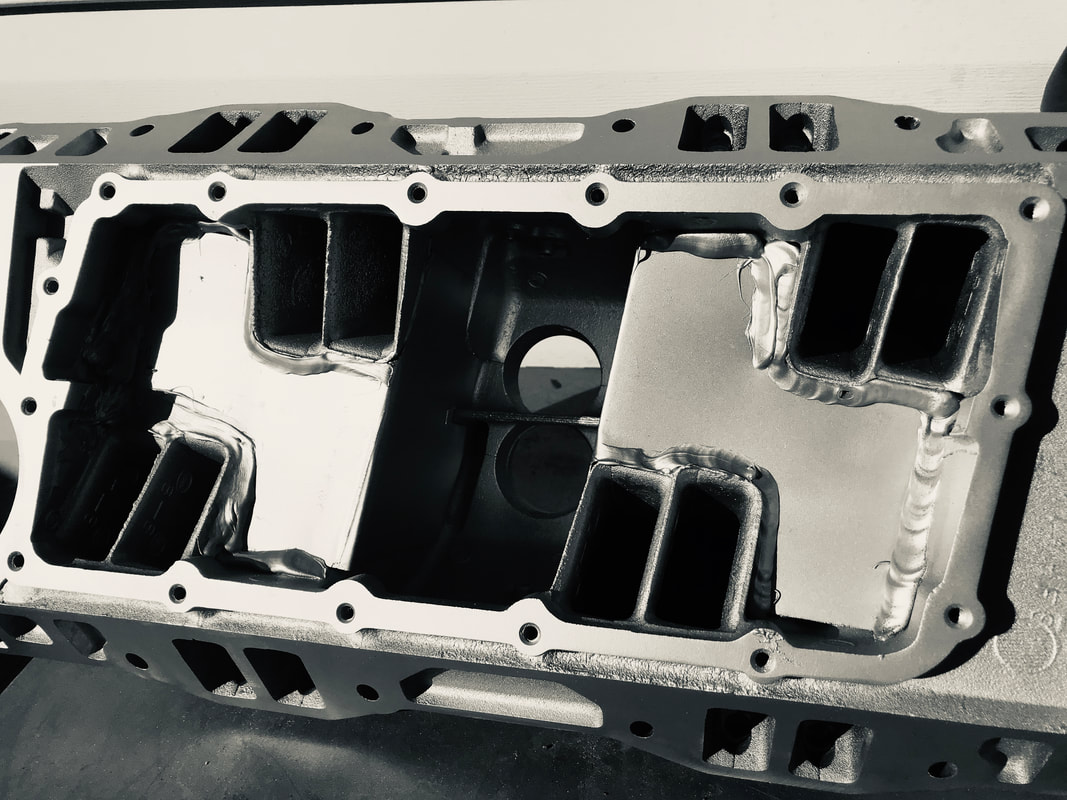

Installation requires a clean, repeat-clean intake manifold. The plates are CNC cut and bent to install in the front and rear of the of the kegger intake manifold. The plates do need to be trimmed for a tighter fit as every intake has core shift and will line up differently. You can have them professionally TIG welded in place or you can secure them as I did on the first set with stainless hardware, 2 part steel epoxy and sealed the edges with RTV. Now I have my local welder spot weld the corners then I used standard spray expanding foam inside the void, then RTV on the edges again. Once done, I properly seal the plenum gasket and make sure I have a oil catch can installed so no oil ever makes it into the intake manifold.

Installation requires a clean, repeat-clean intake manifold. The plates are CNC cut and bent to install in the front and rear of the of the kegger intake manifold. The plates do need to be trimmed for a tighter fit as every intake has core shift and will line up differently. You can have them professionally TIG welded in place or you can secure them as I did on the first set with stainless hardware, 2 part steel epoxy and sealed the edges with RTV. Now I have my local welder spot weld the corners then I used standard spray expanding foam inside the void, then RTV on the edges again. Once done, I properly seal the plenum gasket and make sure I have a oil catch can installed so no oil ever makes it into the intake manifold.

Trimmed to the edges for pre welding prep or epoxy.

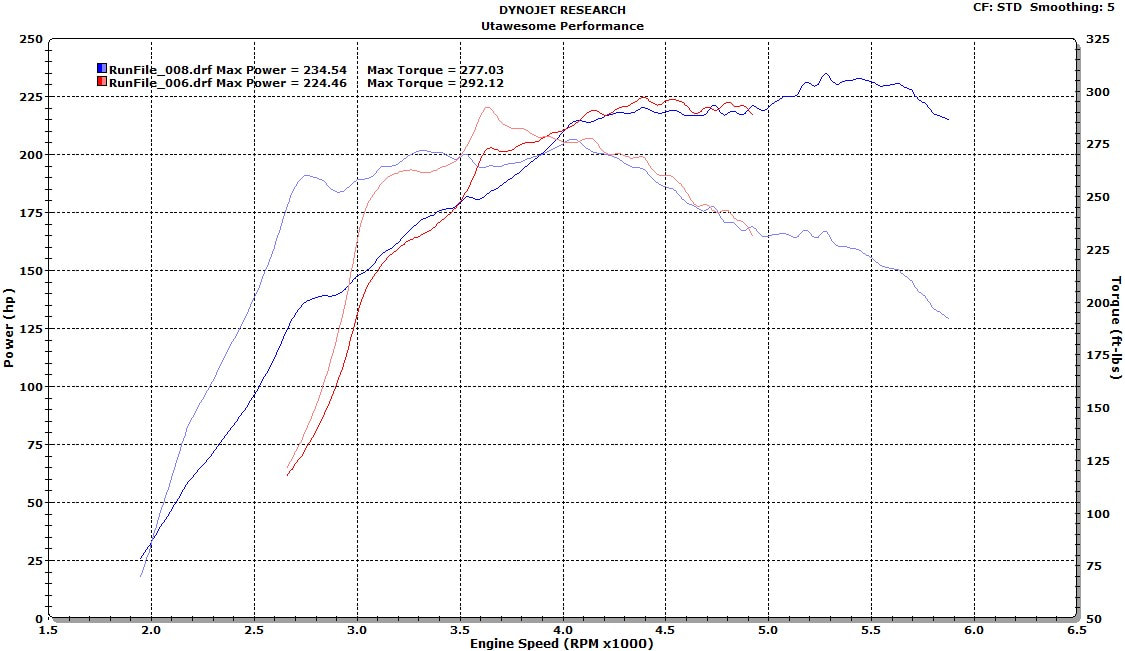

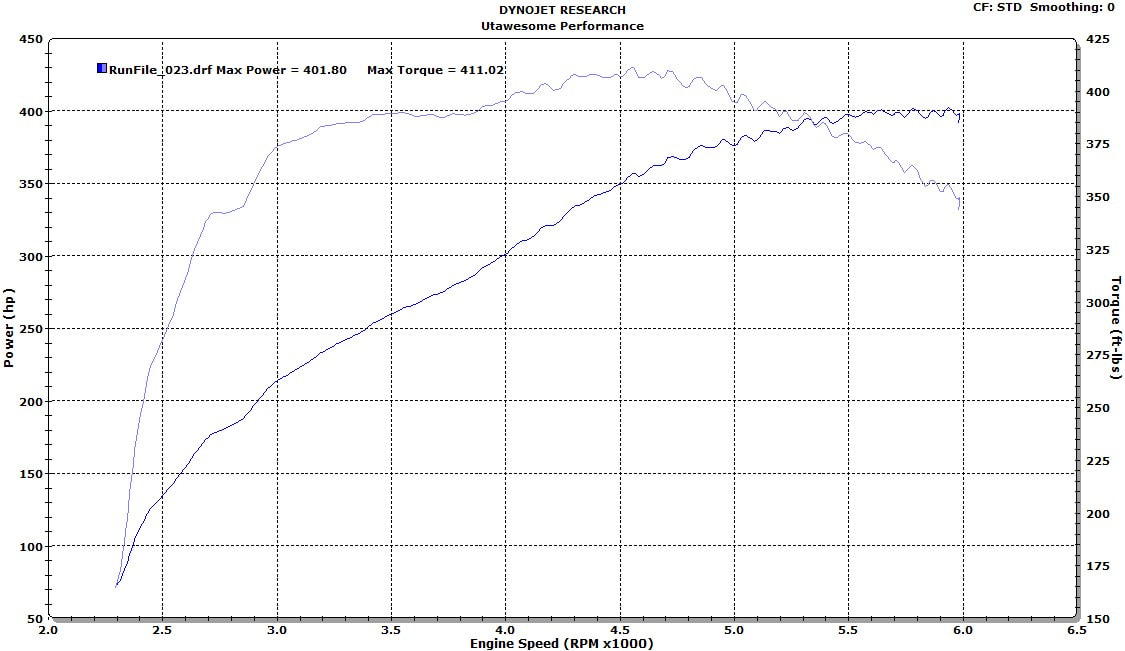

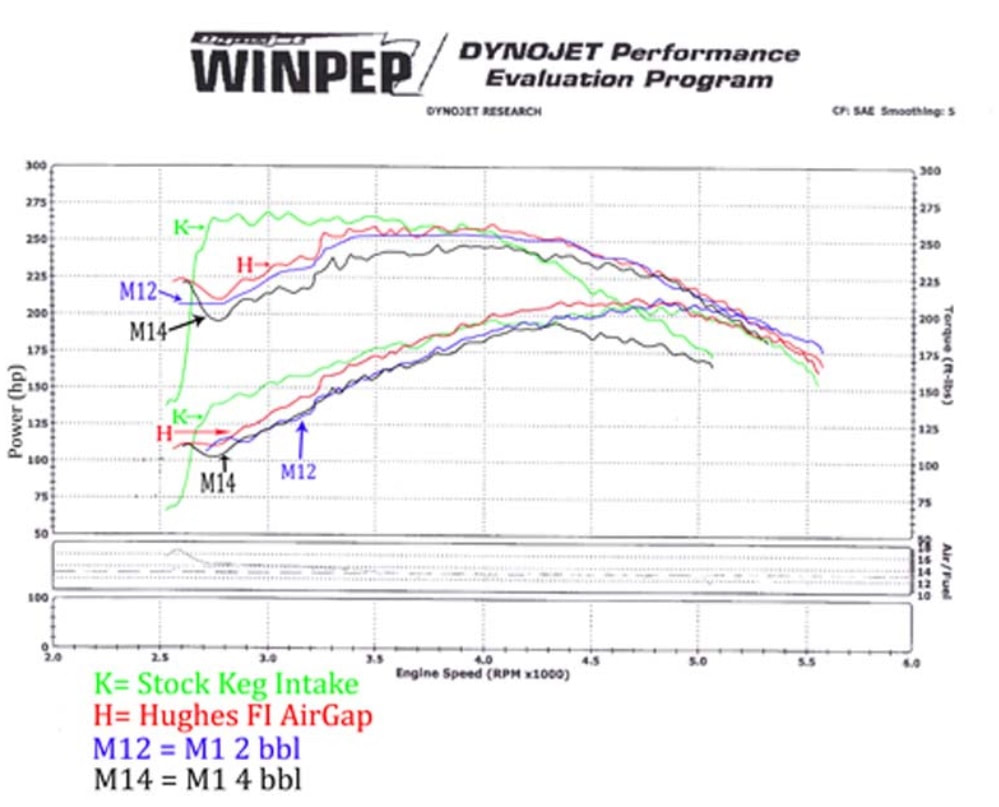

The finished product before it is sealed up with the plenum pan. Please visit the Online Store for ordering details. Below are various M-1 2bbl and 4 bbl Performance intake pulls, some great some not so great. But pay CLOSE attention at the rpm where the peak torque is being produced. That is where the stock ported long runner kegger outperforms it.

The test above performed by Performance Injection Equipment's for Hughes Engines showing on a stock engine what manifold really performs down low...

Review from Dennis C-About a year ago I purchased a 99 Durango with a modified 5.9 Magnum motor. The performance parts were purchased from and recommended by a shop famous for its cams and intake manifolds for LA and Magnum motors. They include: modified throttle body(1000cfm), air gap style short runner intake, roller tip 1.6 rocker arms, engine quest heads with heavier valve springs, roller cam- 208/214@.050 lift .523/.533 with 1.6 rockers 114 degree lobe separation angle, 9.3 calculated compression ratio, JBA shorty headers and an SCT tuner. Gear ratio is 3.92. I believed with this combination the vehicle would perform very well at normal operating RPMs and bought it without driving it very much. Performance was sluggish off idle to about 3000 rpm. At 3000 rpm it had a strong surge and pulled well to 5000 rpm. In normal driving I don’t use that range often. I was disappointed. Finding Utawesome Performance’s website I sent them an email asking if they could assist with a custom tune. I expected to hear “no” or not get a response. Instead, I received a call from Marty to discuss my needs. He sent me several different tunes to try and they did help, moving the “hit” down a couple hundred rpm.

Marty suggested that I needed to replace the air gap intake with a modified kegger intake. He did some mild port work and installed his volume reducing plates. I received the manifold and set aside a weekend for the install. He sent me different tunes to match the intake as well.

What a difference! Now it takes off when you hit the throttle. It doesn’t feel like it’s working to get moving and it really sets me back in the seat. It still pulls hard above 3000 rpm as well. No noticeable loss in upper rpm power. You can have your cake and eat it too!

Thanks Marty!!