"Unleashing Superior Performance: The Revolutionary 3D Printed Throttle Body That Leaves Competitors in the Dust"

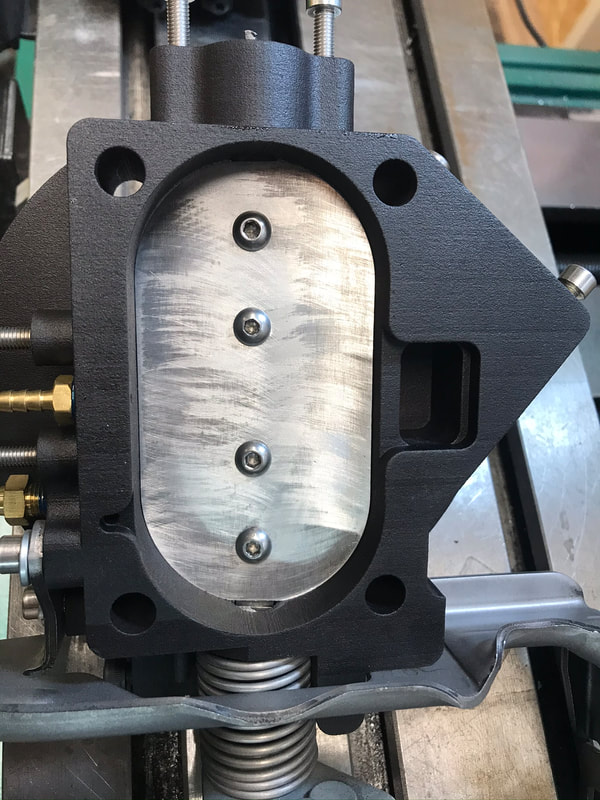

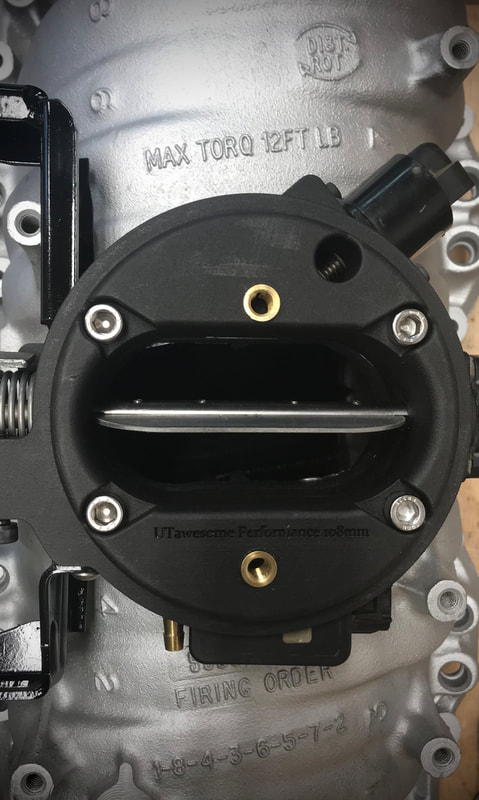

The 3D printed throttle body showcased in this article is a game-changer in the Magnum industry. Crafted using the HP Fusion Jet Sintered Layering System printer, this throttle body boasts exceptional design and material composition, setting new standards for performance.

Featuring an angled Idle Air Control (IAC) motor location for improved sensor access and a clocked Throttle Position Sensor (TPS) mount providing precise voltage readings, this throttle body demonstrates meticulous attention to detail and optimization.

Thanks to the HP Fusion Jet printing technology, the 3D printed throttle body is void-free and completely free of layer lines commonly found in traditional Fused Deposition Modeling (FDM) printers. This ensures unparalleled flow capabilities, with an impressive flow rate of exactly 1300 cubic feet per minute (cfm), surpassing the stock aluminum throttle body's 600 cfm.

Not only does the 3D printed throttle body excel in airflow, but it also outperforms aluminum counterparts in heat dissipation. Its plastic composition efficiently dissipates heat, making it a superior choice for high-performance applications.

Real-world testing, specifically on the "Engine Masters" show, has proven the remarkable performance gains delivered by this throttle body. Across the entire rpm band, testing experienced a increase of 12 horsepower and 12 torque compared to stock throttle bodies. These figures showcase the significant power and torque enhancements that can be achieved with this groundbreaking 3D printed innovation. Increase continue further with mods greater than stock as it is not limiting airflow to the combination.

The testimonies of satisfied customers, industry experts, and the recognition received on the "Engine Masters" show attest to the exceptional performance and advantages of this throttle body. Their first-hand experiences solidify its position as a cutting-edge solution for Magnum enthusiasts seeking superior power delivery, efficiency, and overall performance.

With its innovative design, superior flow capabilities, heat dissipation, and remarkable performance gains, this 3D printed throttle body leaves competitors behind, setting a new standard for Magnum builds.

The 3D printed throttle body showcased in this article is a game-changer in the Magnum industry. Crafted using the HP Fusion Jet Sintered Layering System printer, this throttle body boasts exceptional design and material composition, setting new standards for performance.

Featuring an angled Idle Air Control (IAC) motor location for improved sensor access and a clocked Throttle Position Sensor (TPS) mount providing precise voltage readings, this throttle body demonstrates meticulous attention to detail and optimization.

Thanks to the HP Fusion Jet printing technology, the 3D printed throttle body is void-free and completely free of layer lines commonly found in traditional Fused Deposition Modeling (FDM) printers. This ensures unparalleled flow capabilities, with an impressive flow rate of exactly 1300 cubic feet per minute (cfm), surpassing the stock aluminum throttle body's 600 cfm.

Not only does the 3D printed throttle body excel in airflow, but it also outperforms aluminum counterparts in heat dissipation. Its plastic composition efficiently dissipates heat, making it a superior choice for high-performance applications.

Real-world testing, specifically on the "Engine Masters" show, has proven the remarkable performance gains delivered by this throttle body. Across the entire rpm band, testing experienced a increase of 12 horsepower and 12 torque compared to stock throttle bodies. These figures showcase the significant power and torque enhancements that can be achieved with this groundbreaking 3D printed innovation. Increase continue further with mods greater than stock as it is not limiting airflow to the combination.

The testimonies of satisfied customers, industry experts, and the recognition received on the "Engine Masters" show attest to the exceptional performance and advantages of this throttle body. Their first-hand experiences solidify its position as a cutting-edge solution for Magnum enthusiasts seeking superior power delivery, efficiency, and overall performance.

With its innovative design, superior flow capabilities, heat dissipation, and remarkable performance gains, this 3D printed throttle body leaves competitors behind, setting a new standard for Magnum builds.

|

|

|

|

|

|

108mm V-10 Magnum Throttle body

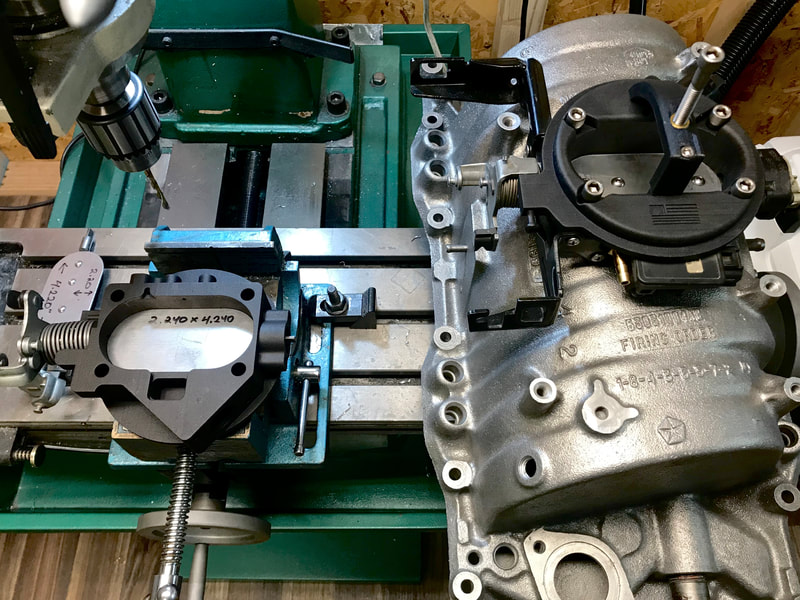

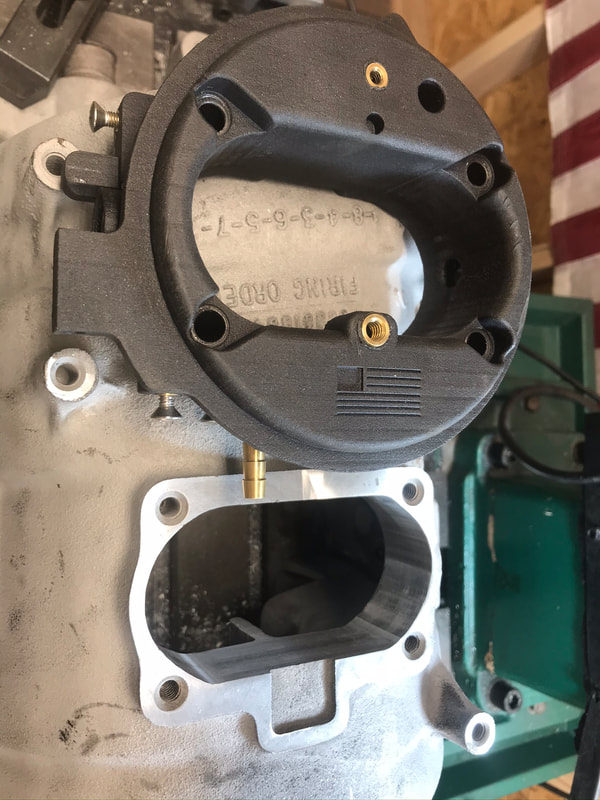

V-10 Intake manifolds have to be clearanced for the 108mm. The runners are thin and not much more than 0.010" can be taken without using sheet metal and block epoxy. The Stock Kegger intake as you can see from the main photo up top must be opened up to use the 108mm. The Hughes Airgap, M-1 2 and 4 bbl manifolds only need small machining to match the opening. The 108mm was flow tested to the Accufab 1285cfm oval throttle body using a digital manometer and 6hp vacuum motor. The 108mm was within 1% the flow of the Accufab. It is important to note that the age old argument of too much flow hurts. Well on a carb setup yes. With the proper combination of parts, such as cylinder heads, camshaft and intake runner length, you can take great advantage of this flow. Now you surpass 1300 cfm and then the numbers fall off in the lower rpms. Stay tuned for the LSA roots supercharger using this very throttle body going on the 360ci and 408ci for dyno testing.