|

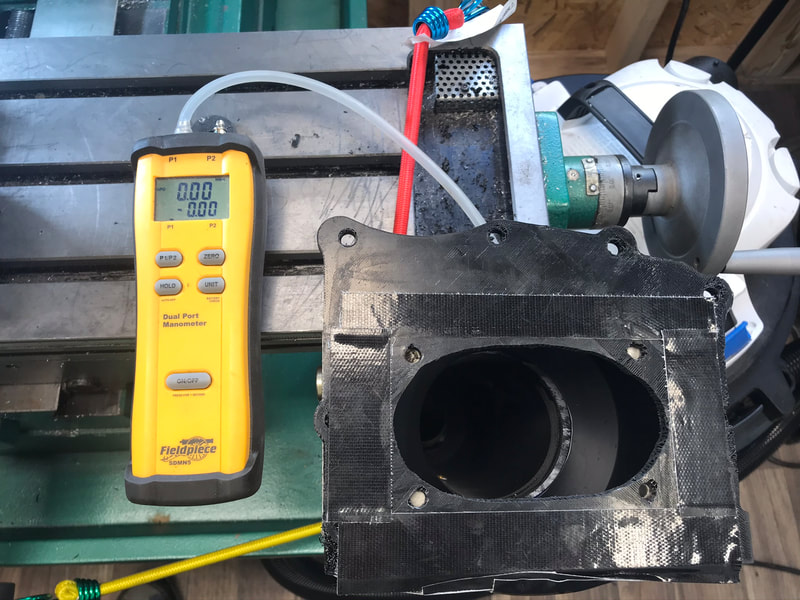

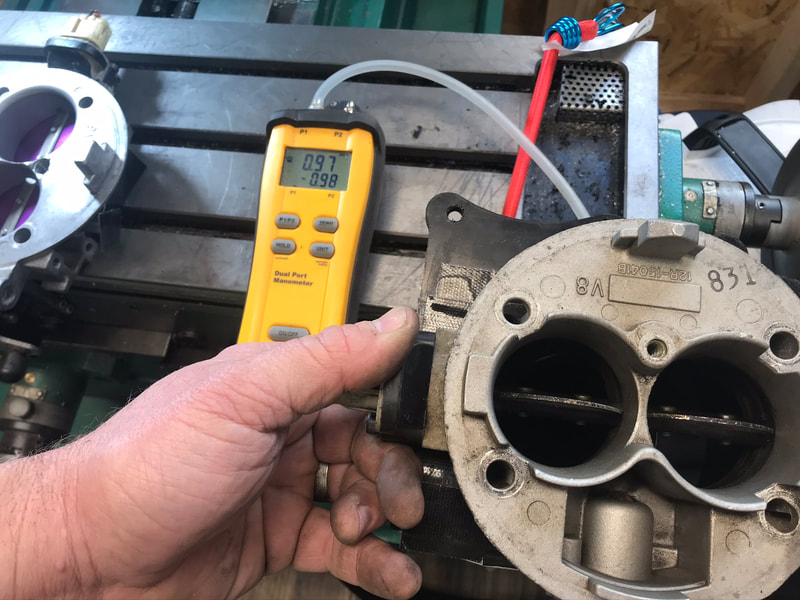

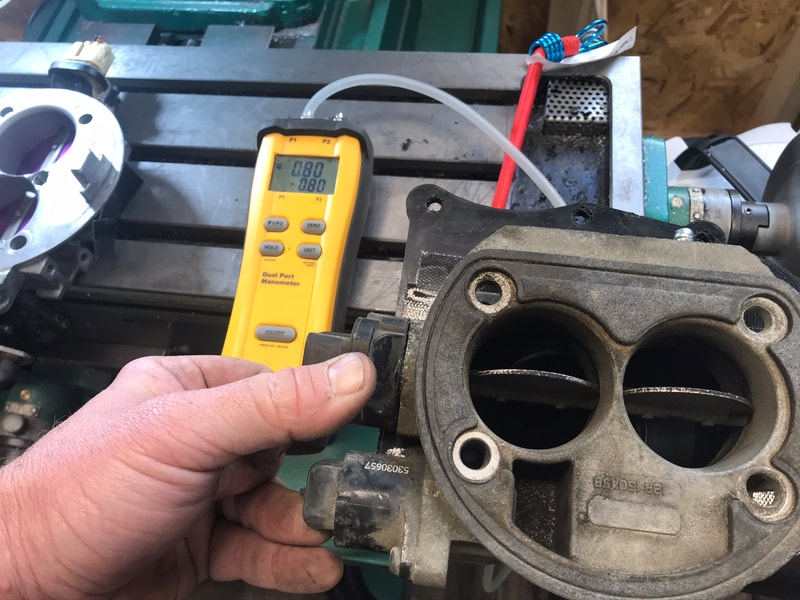

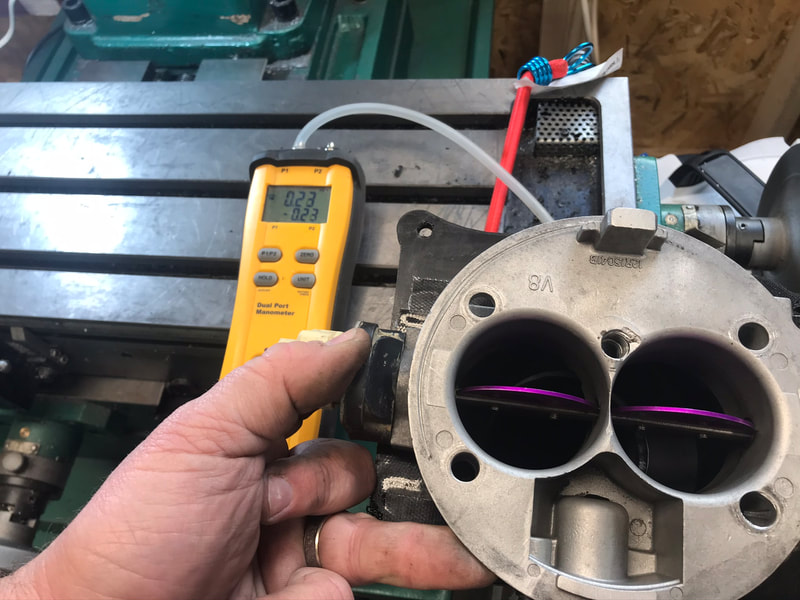

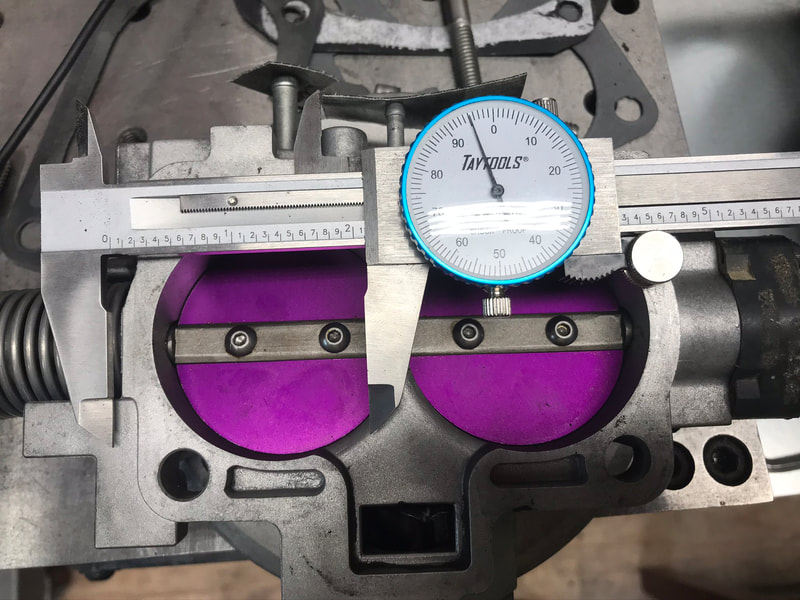

Digital Manometer throttle body flow testing on a sealed 3d printed fixture using a 6hp vacuum motor. IAC, Evap, Map and TPS ports blocked on all throttle bodies. Starting with no TB and open plate, the manometer is zeroed with 6hp flow. Then with the throttle bodies sealed to the plate with the alignment pins centering them in the same position, each TB is then opened to max flow. The loss in flow is then recorded. This is not a CFM measurement, only the flow loss in mm/w at wide open throttle.

Stock TB's flow ~673 cfm @ 28". The AccuFab Oval flows 1284 cfm @ 28". Here is the results of flow test. First is the stock V8, second is the stock V10, third is a thinned shaft 53mm, forth is the UTP 108mm, final is the AccuFab 1284cfm oval. Currently I am printing out a new baseplate to seal the TB's even more to reduce any major differences in flow. But as you can see, the baseline is still the same. I did use the Variac to set the 6hp vacuum motor to the same current for each TB. When the new 108mm throttle body is released in April, I should have the CFM flow specs for it. But it is important to not get caught up in the CFM numbers game. You are looking for a flow "difference" from a starting point. I use the same jig on the intake manifolds to get the runners as close to each other in flow. You can set up the manometer to measure velocity with a port probe, but for now, I simply needed the restrictions measured. Maybe in the future I will score a Superflow 600 (even though 600cfm is the limit) Using for the throttle bodies, you can see a well worked stock throttle body with thin shafts and 53mm blades is a great flowing performer. These are easily 900cfm+ and don't confuse this measurement with a carb that flows the same. But if you need greater velocity and flow, the UTP 108mm is a 1250-1270 cfm winner! Stay tuned for the April release!

0 Comments

|

Marty FletcherHands on engine builder and tuner for Dodge since 1993. Archives

July 2023

Categories |