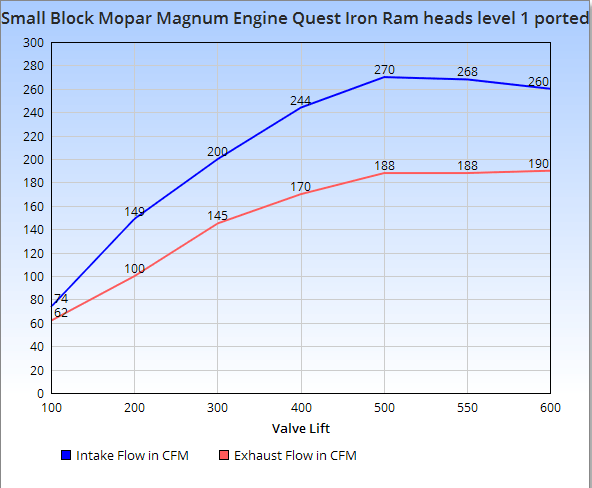

Looking for an excellent replacement for your aging stock Magnum heads? Look no further for quality than the Engine Quest heads direct replacements. I have been doing business with Performance Injection Equipment for years and can tell you from experience, their detail on these heads perform. Many years ago I literally sold thousands of Mopar Performance R/T casting heads. I had mild to fully ported, 2.05 and 2.08 valve combos, turbo setup and even spent a lot having an O-ring tool made before Cometic gaskets put an end to that need. Many people ported the heads for me back then (Chapman, PIE, LPM Performance and the late Lennart Bergquist, who was the Jegs Engine Masters winner in 2005). So when EQ released the replacement heads, word was out that the flow was increased, not as much as the R/T casting, but well beyond the stock Magnums. Now many competent porters will tell you the Magnum head could be worked well to support 250 cfm, but the narrow pushrod pinch could only be worked so much. It does no good to port the exhaust side to outflow the intake, unless it is a turbo setup -and that should be aluminum. Rule of thumb was to keep the exhaust at 75% flow of the intake flow.

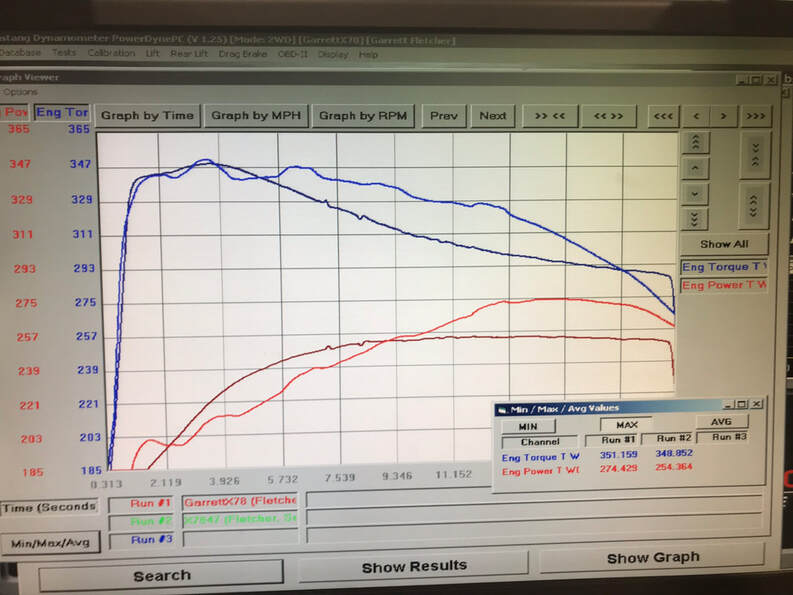

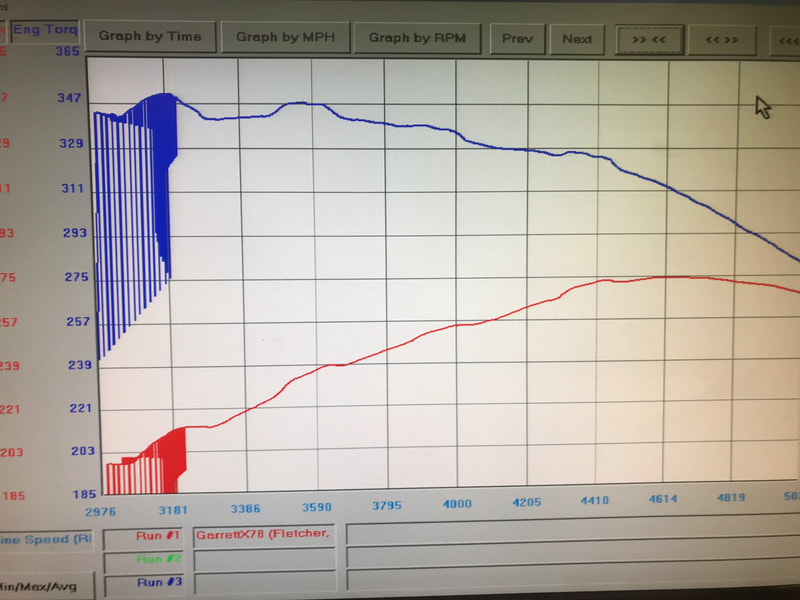

When I developed the UTP cam lineup, I picked a lift that stock heads flow 213-215 cfm at. I kept the torque high by keeping a single pattern in-tune with the stock long runner intake manifold. I have run every combo in the years past (25 to be exact) and simply put, you always needed a set of steep gears and convertor to make up the low end loss on the shorter runner manifolds at lower rpm. So running a UTP450 cam on stock Magnum Heads with shorty headers and a tune resulted in the following dyno: 254 horsepower and 348 torque.

You can already see on the graph the change to the EQ heads. But lets get some more info first before I chime in on that run above. I ordered the Level 1 heads from Chris at PIE. They are posted with the following:

- Stock location for headers, valve train, and front end accessories

- 2.02" stainless intake and 1.625" stainless exhaust valves

- valve spring 125# seat 315# open @ .575 lift max

- 8mm valve stems

- 172 cc intake runners and 72 cc exhaust runner

- 62cc combustion chamber

- Ductile iron exhaust seat to reduce cracking

- Manganese bronze valve guides

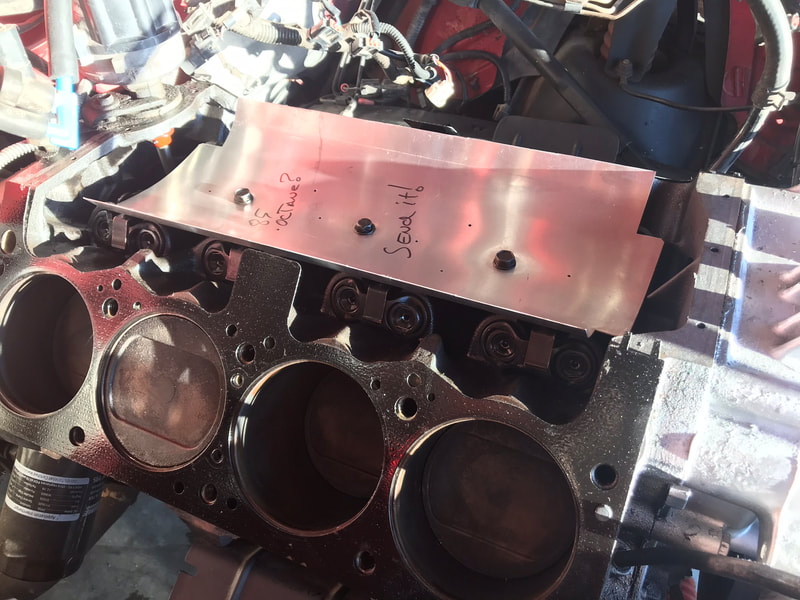

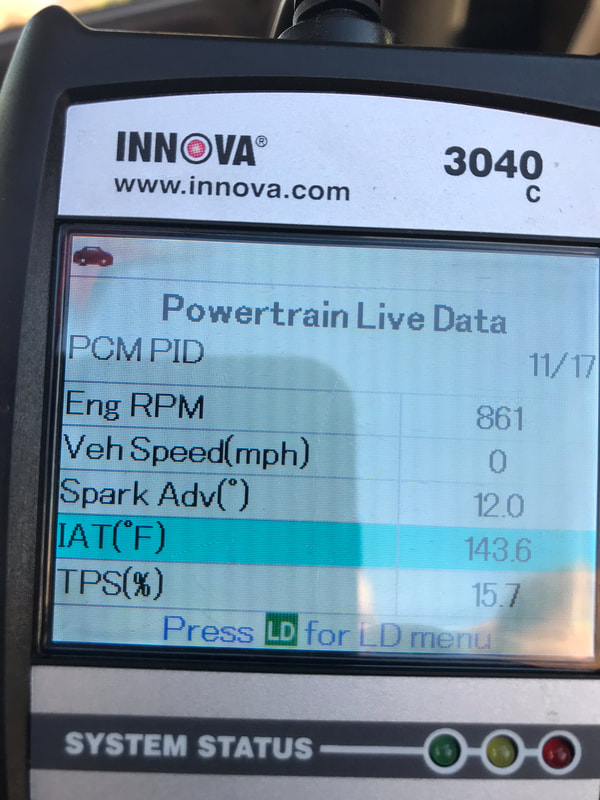

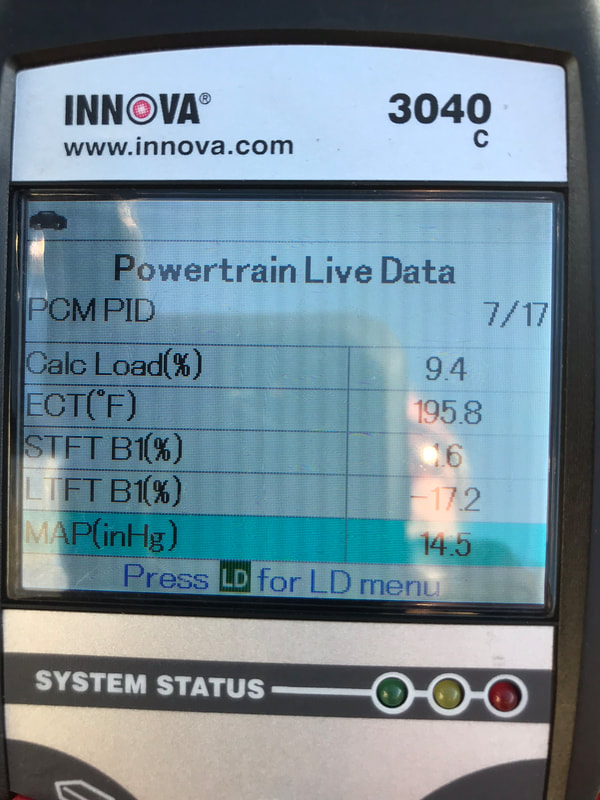

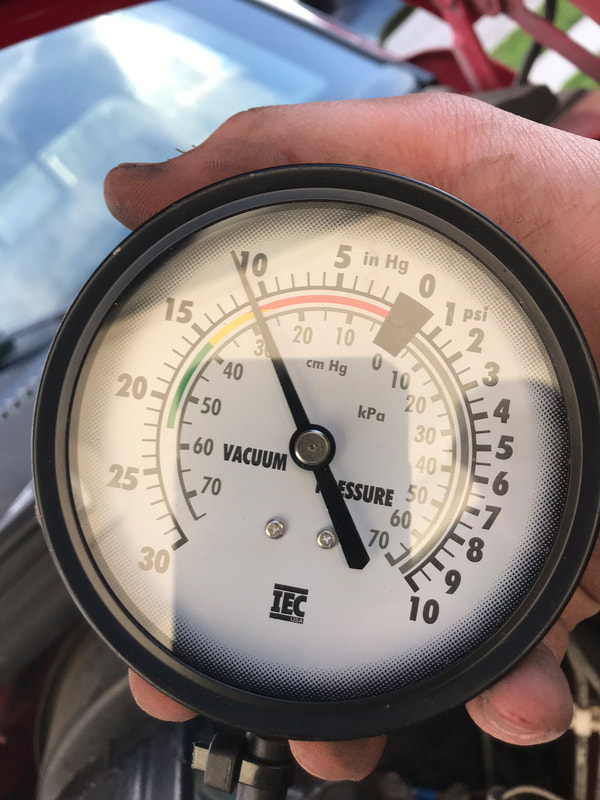

The last 2 photos show the stock Magnum head crack I had been running along with the cheap shorty headers. With all that it still laid own 250 rear wheel and 350 tq at 3000 rpm. Performance Injection Equipment used the 2.02 valve above for the new setup. In all fairness, I changed more items at once instead of eating up dyno time for individual changes. I increased my compression by running the 0.028" thick head gaskets from Mr.Gasket (LA yes), ran the new VRP Plates in the kegger manifold, installed the valley pan shield to keep the hot oil off the bottom of the intake and added the DNA Motorsports longtube 1 3/4" primary headers. Once running, the tuning changes quite a bit. The first thing I noticed is that I had to increase my part throttle fuel enrichment tables as it wanted some fuel. Second, to achieve 12.8 afr at WOT, the injectors being stock are sitting at 93% for that short time. I have new 36lbrs going on as of this writing but the test was done with stock. No longer were the IATs at 200 degrees here in Utah, they dropped to the 140-150 range. I also gained a small amount in vacuum from 9-10" to 11". Stock pushrods and rockers went right back in place with sync set to +4. 32 degrees advance. As you can see on this 4x4, the headers cleared, but I still clearanced them as they were super close to that choppy camshaft engine rocking.

Once strapped onto the dyno at API Performance in Sandy Utah, regular 88 eth free fuel was used and tuned. As you can see on the dyno at the top we gained an impressive 22-26 rear wheel from the previous 248-254 average. The best part was the torque stayed the same peak but made an impressive gain from 3600 rpm to 5200 rpm! So in street configuration, the Ram puts down 274 and 350 tq enough to be 350-360hp and 450tq at the crank all through a kegger. So now we are going to step it up a notch on the Silver Ram that runs the UTP500 cam. That truck layed down 336/400tq through a ported kegger and stock Magnum heads. We are ordering their Level 2 heads, reworking the kegger to flow 260+ cfm. You can ask PIE what valve job and specs they run, I am not going to say as that is his proprietary information. But the correctly sized bronze guides, excellent RA finish on the surface and attention to cleanliness is what we got. So if you need a great set of heads with excellent power potential, give Chris a call at Performance Injection Equipment 302-858-5145! https://www.performanceinjectionequipment.com/