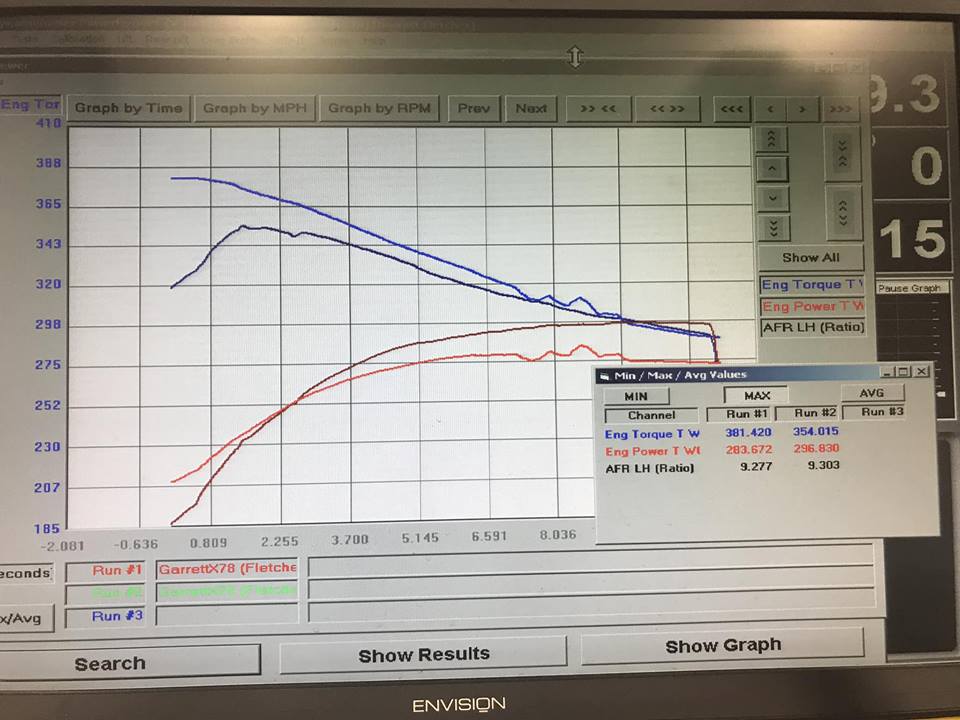

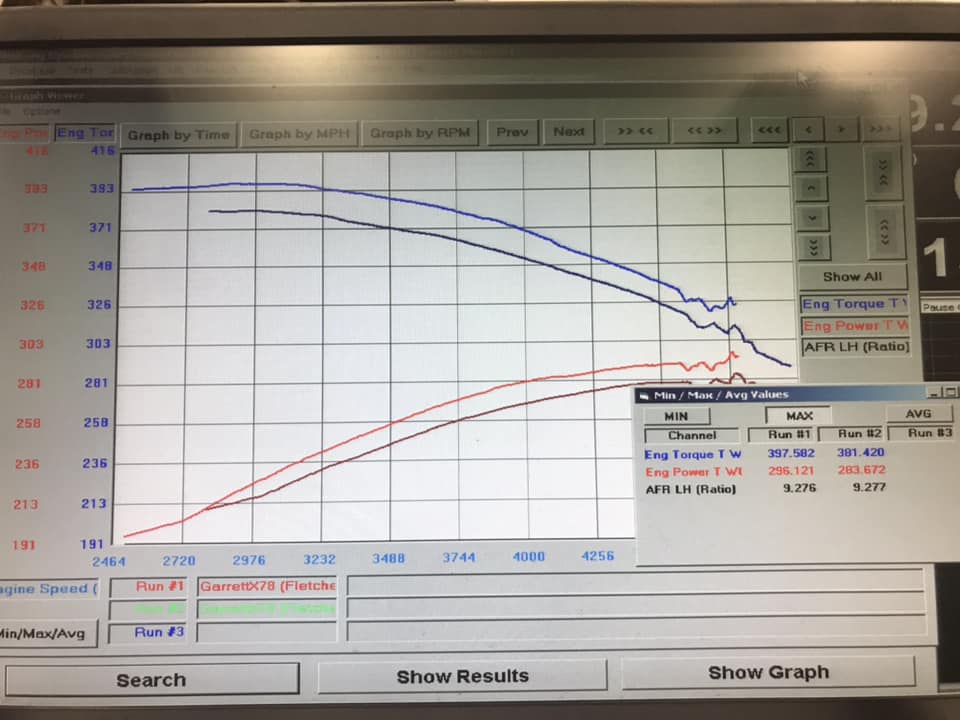

Do you have a secret? Hidden and buried far in the recesses of your neural network? Something that you are guarding, so that it never gets out to anyone but maybe a chosen few? Well, I don’t. Concerning my engine building and tuning skills, there are very few things I keep to myself. I share it on my website, and in the forums for all to take it or leave it. Here is the interesting story of the Dodge Truck intake manifold concerning my work and its impact on the world. First, for those who do not care to know the details, I promise not to bore you to death with technical jargon and flow numbers. I am simply going to start from the beginning and paint a picture in your mind of this long trip I have been on. Way back in 1992 the engineers at Chrysler/Dodge redesigned the old 318 and 360 cubic inch V-8s. Their work added a newer roller camshaft, hydraulic lifters, revised cylinder heads, higher flowing exhaust manifolds and a long runner redesigned intake manifold. They coupled that with the latest multiport fuel injection to produce 230 horsepower and a whopping 345 torque for excellent smooth power and efficient fuel economy. It was years ahead of the old throttle body injected low power 318/360s of 1970-1991. It did not take long for the aftermarket to notice these engines and soon, you could buy headers, exhaust, camshafts and Mopar Performance released special recalibrated computers for even higher horsepower gains. Finding those today is like finding a gem in Solomon’s Mines. But I imagine there are many out there in junkyards across the USA if you take the time to search. So moving on, I am going to tell you about my interesting story of that redesigned intake manifold and how it has changed my business sales almost three decades later. Somewhere around the years 1999-2000 Mopar Performance finally released a fuel injected version of the intake manifold dubbed the M-1. My speed shop at the time literally sold thousands and was reported the highest sales by Mopar Performance for this intake manifold. Literally every truck that came into the shop, had the stock intake pulled off and thrown into the garbage to install these performance manifolds-along with other matching items. In my quest to produce the best and highest horsepower numbers on our dyno (a machine that measures the horsepower of the engine) we ignored the loss in torque and concentrated on the horsepower. Mainly, because that is what sells- as torque is too often misunderstood. We give too much emphasis on horsepower instead of torque. Even this article is named Horsepower Secrets, not Torque Secrets for a reason. So with all the high flowing cylinder heads and intake profiles making high horsepower, I noticed we had to install steeper rear end gears and higher stall torque convertors in the transmissions to get the truck out of the gate faster. I made sales on those additional items so it was never a question to change my thinking. Come forward to 2018 and I found myself moving to the higher altitudes of Utah and lack of oxygen up here really made for gutless engines. Back down at sea level, they ran outstanding, but up here I lost almost 35% of my power. That is over 80 horsepower and torque gone! Second, I had all these customers who had followed that old recipe of installing the short runner high rpm M-1 intakes on their trucks, yet they were complaining they could not spin the tires. They had been fed a lie that the stock intake is worthless. What they failed to realize is that they needed torque at a much lower rpm in those heavy trucks than that performance manifold would ever deliver. So I began my testing on the stock intake manifold that began with all the nay-sayers posting up comments such as ‘waste of time, worthless’ and many others I will not repeat. First I started with a stock 360, reprogrammed it and then redesigned the camshaft profile to a single pattern compared to the split pattern that even the factory had used. Single pattern cams in the past have always been known to produce more torque than a split pattern camshaft. I was rewarded with a 60 foot pound gain of a camshaft change only. Most dynos across the US had reported measured torque around 270-280 and here was mine at 350 torque using the stock intake manifold. Next I worked on calculating the airflow the cylinder head needed and how restrictive the stock intake manifold really was. It actually was not that terrible. I found myself going to my favorite junkyard and buying up stock intake manifolds. The old method for budget racers was to shorten the long 18” runners to 16”. This gave them gains in the midrange and upper rpm as the stock intake usually stopped making power past 4500 rpm. I changed that up and not only shortened the runners but opened the inside of the runners up with super long porting bits that could reach in there. I had my baseline measured numbers from before, so I would test each configuration on the dyno. Some results were good others where terrible. At one point my torque fell from 360 down to 300. But then the greatest change came when I decided to reduce the volume area inside the intake manifold in hopes of speeding up the velocity of the incoming air. To do this I simply cut up some sheet metal and trimmed it to cover up the huge voids in the intake manifold. Once I sealed it and painted the manifold, I posted up a picture of my mad science for the forum to see. As usual there were two camps, those who were interested in seeing what the outcome was going to be good or bad and those who said it would never work. Discussions of velocities, cross sectional areas, individual port starvation flooded the forums with this crazy experiment Fletch was up to. So early in the morning, I installed the intake manifold and scheduled to rent the dyno in the afternoon. The first thing I noticed driving was that the truck had excellent torque and effortless throttle just driving around town. It did not feel any stronger at wide open throttle and I have learned that even though something may feel better on the street, the dyno will break your heart and show a loss. So everyone waited as the afternoon dyno appointment approached. As I arrived and strapped down the truck for the test, I had to tell myself that even if it was terrible, I would continue to push the research. My best numbers before on a fully ported 18” runner intake were 297 horsepower and 354 torque. Now I had a non-ported intake with only the volume reduced in half. It was time- I stabbed the throttle as the engine roared to 5000 rpm. My wife was taking video of the run and plugging her ears at the same time as the engine ran through the test. To everyone’s surprise, the first pull was 283 horsepower and a whopping 381 torque!! I had only lost a few horsepower and gained 27 foot pounds of tire shredding torque. I knew from my past test that just letting the engine cool down between runs was a sure fire way to increase those numbers. So we let it cool down with a fan for 15 minutes. During that cool down time, I posted up my first dyno run real time with the video and the forums ignited like an IED on the road to Bagdad. It was time to make the second run. Engine on, gearshift in drive and throttle rolled into, I opened her up. The engine roared to 5000 rpm again and I let off when the test showed complete. I nearly fell out of the truck as the dyno trace graph posted 339 horsepower and massive 404 foot lbs. of torque at 2900 rpm! The dyno has weather and altitude correction factors and when pulling up the graph, it showed a smooth gain and corrected numbers of 296 horsepower and 397 torque. Never before had anyone posted a stock intake manifold making anything over 300 tq yet here it was at 400 plus. That meant that that engine had to be producing 490 torque at the crankshaft. The most amazing part is that nearly 90 percent of the guys running the performance M-1 manifold and head combos are only making 330-340 tq. What is the moral of the story? Never under estimate factory designed parts, as millions of dollars were spent designing them and no easy thoughts went into that. So remember when you build for torque, the horsepower numbers will fall into place. As my old Pops used to tell me growing up- “Son, horsepower is how fast you will hit the wall. Torque is how far ‘through’ the wall you will continue.”

13 Comments

|

Marty FletcherHands on engine builder and tuner for Dodge since 1993. Archives

July 2023

Categories |