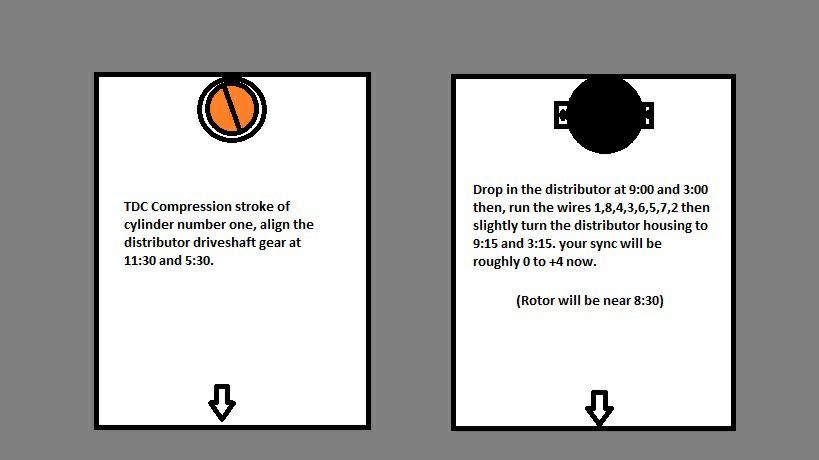

So you moved your distributor or changed cams and now the truck is running strange? What gives? Can I just throw my timing light back on my 92-2003 318 and reset it? Must be the tune right??? Not just no..... Moving the distributor does not change your spark~that's right, does not change it. What you do change is WHEN your injectors fire. The time is called cam sync- which is related to your crankshaft position sensor. You can imagine what happens if your intake valve has just closed and then your send fuel in the runner. You just missed your cylinder fill window for that cycle. Underneath the distributor is a gear driven by your camshaft called the oil pump driveshaft. That's right, it is what turns the oil pump downstairs and the distributor upstairs. When moving that oil pump driveshaft by changing cams, it has to be set back up to properly fire your injectors. Once you have mechanically set the steps above, you can put a scanner such as a Matco, SnapOn or DRB to set the sync. It will display sync OK if it is between -8 and +8. In the performance world, we always set to +4 to throw the mix right as the valve is opening with velocity. No scanner though? Simply follow the clocking directions above and you will be super close. Here is a great article below that will help you understand further details: (although I may actually be the author from the Bionic Dodge days...) Magnum Engine Distributor Removal, Replacement, Re-syncing When the distributor is removed and replaced in the magnum (fuel-injected) engines, the distributor must be synchronized to properly time the injector pulse (spray), similar to the ignition timing for the spark plugs. The distributor does not control the spark timing that is controlled by the computer. When the distributor is re-installed you need to get the sync close enough to start the engine so you can get it properly synced. If the intermediate shaft was removed, as when replacing the camshaft, it must be correctly positioned before the distributor is installed. The slot in the top of the intermediate shaft must be positioned so that the slot runs from an 11:00 o’clock to a 5:00 o’clock position when cylinder #1 is at TDC compression stroke ( if the shaft is straight front to rear that is the 12:00 o’clock to 6:00 o’clock position). Once the intermediate shaft is correctly in place, the distributor can be installed. Bring the #1 piston up to top dead center (T.D.C.) on the compression stroke. Remove the #1 plug and you can feel pressure coming out of the plug hole on the compression stroke. Line-up the T.D.C. mark on the damper, with the “0” mark on the timing tab, on the timing chain cover. Install the distributor so that the rotor is lined with the small notch in the plate that covers the top of the distributor base. This mark will time the injectors to pulse close enough to get the engine started and run. Proper final synching should be done with a dealer’s scan tool DRBIII or Snap-On Scanner. The information given here is based on those scanners. Other scanners may not read exactly like the Snap-On. Setting the sync using an ohm meter is not recommended or accurate. Using a scanner, the idle is brought up to 1000 rpm, to reduce valve train fluctuations and the sync signal set to zero. Most of our cams can use 3-5 units advance/positive. Note: This advance setting is only applicable when using the Snap-On DRBIII Scanners. The units are not all the same on other scanners. If you do not have a scanner that can do this, then pay to have the dealership do this. Some of the symptoms that the sync signal is incorrect, you will get back firing through the intake manifold; vehicle will not idle or you will get major detonation at light loads causing the vehicle to lose severe power over 3000 rpm.

5 Comments

Nathan

8/6/2019 08:53:10 pm

I got my sync at +1but moves are some up +3 with the snap on scanner hooked up and going down the road look a the current sync will read ok but some times with light load around 2500 to 3000 rpms I lose sync I can stop and cut it off or drop to N and cut it off then start it but up and sync will go back ok till misses but fuel sync stays at +1 to +3 range I can ease off when it starts to miss the get back on and it will go on down the road or when start to miss I can floor it and straightening up

Reply

Marty

8/7/2019 07:18:27 am

Nathan-sync is only read in park at 1000 rpm to eliminate valve train fluctuations. You set it 2-4 and that is it. The window is actually -8 to +8 and you will still be in specs. If you have lost sync codes, possible issues are extreme valvetrain slop such as a timing chain that is loose, loose distributor bushing or more than likely the camshaft or crankshaft sensors are in need of replacement.

Reply

7/28/2021 08:29:46 am

Yes I get the same with my 2001 v8 dodge. Set it numerous times but it still misses at high revs in park

Reply

Daniel

7/13/2023 11:53:43 am

Do you have a write up for setting sync on obd1 vehicles where you don’t have an OBD2 port to plug in a scanner?

Reply

Dan Jones

8/17/2023 04:32:40 am

When I set my cam shaft ,Syn the closest I can get is 0-2 degrees. Is this caused by worn distributor?

Reply

Leave a Reply. |

Marty FletcherHands on engine builder and tuner for Dodge since 1993. Archives

July 2023

Categories |