|

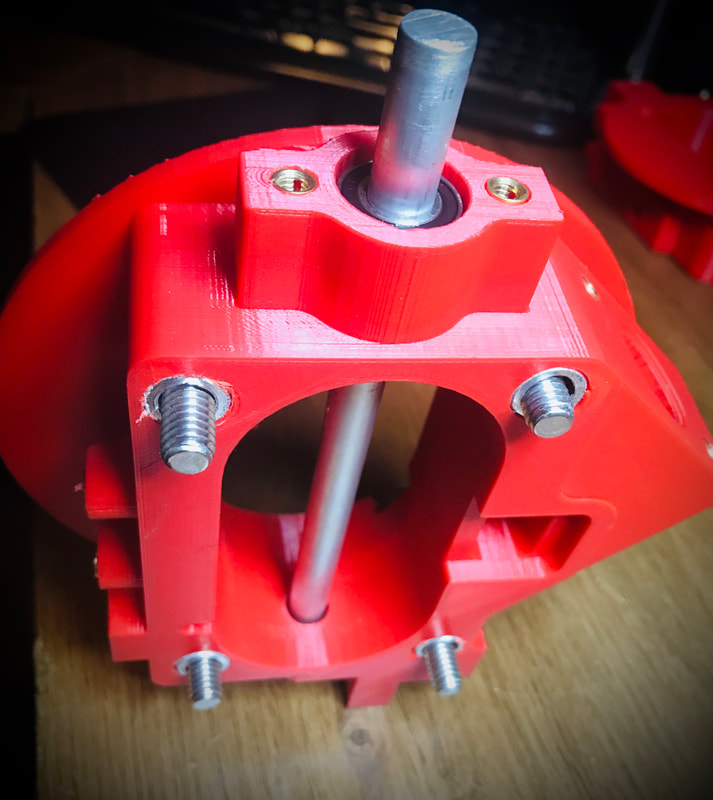

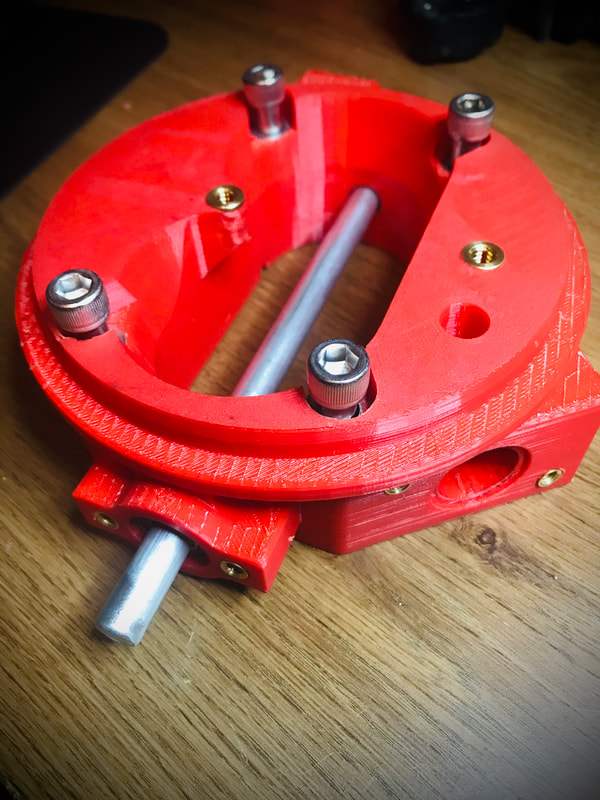

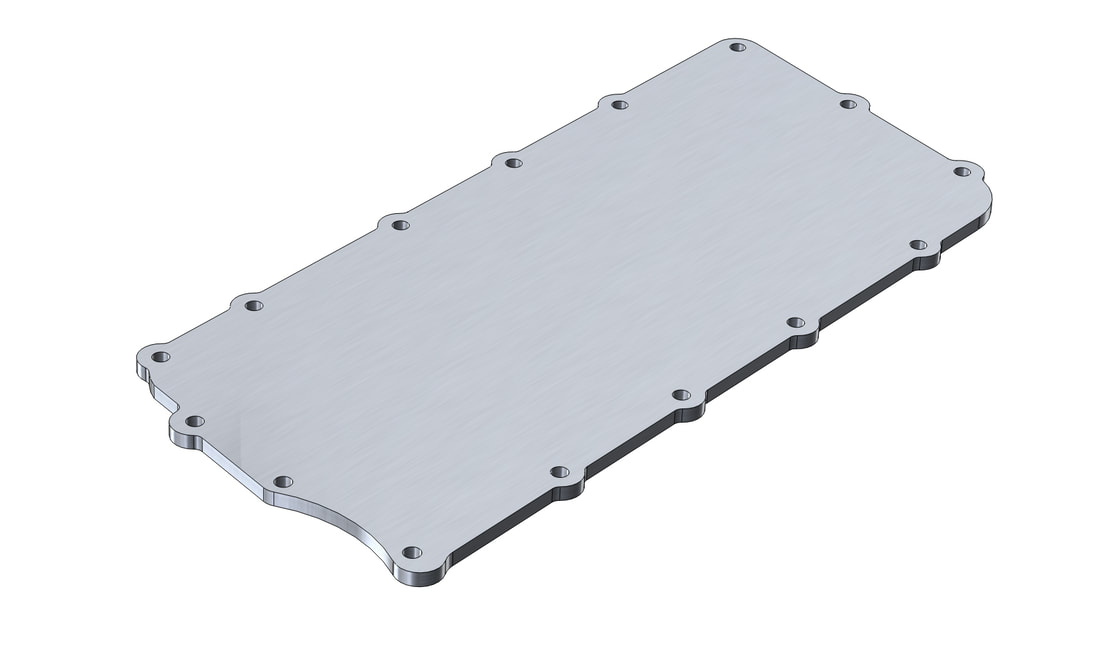

So in my last dyno video of the test truck running the UTP500X cam, I made the comment that the Magnum heads (stock 'cept for valvesprings) were done and squeezing any more out of them would be tough. Boy was I wrong. We installed the new modified Kegger intake, raised the floor 1.7" reducing the volume, cut the runners to 7" in length, then ported to 2.3 cross sectional area. To mix it up further, I machined a AccuFab 1280 cfm oval throttle body on top with throttle and kickdown brackets to match. The dyno is scheduled soon and numbers will be up to compare to the previous 336rw 403 tq. But what is cool about this combo is it is simply 4 major items on a fresh rebuilt 360. Long tube headers, modified intake, camshaft and a tuner. Other cool items are a smaller crank pulley, Mopar windage tray, UTP Valley Pan heat shield and a trans built by Randy's Transmission Tooele Utah. This is all on stock cracked Magnum heads. Next are a set of Performance Injection Equipment ported Edelbrock heads. All the old theories of 'how a 52mm TB can hurt you' and 'Keggers never see anything over 4500 rpm' are finally put to rest. Its time to stop running carb intakes and step into the 21st century with tech. With that, my little shop is finally complete. My vertical milling machine and 3D printer are working hard to churn out some cool stuff. I am porting stock intakes, setting runner lengths for customers now. The 3D printer is a large volume enclosed G Code CAD machine that is currently assigned to printing out Poly-carbonate infused with Carbon Fiber throttle bodies. The first design is a mono blade instead of two bores. It has a 20% larger flow area over stock. Once the CNC shop finalizes the throttle shaft and blades, I can start assembling these lightweight heat resistance super strong throttle bodies. Testing will be done for about two months with selected customers plus our Rams here. This design will work on M1 2bbls, 4bbls , AirGaps and a kegger that has a throat venturi machine to match the old M1-2bbl. All Keggers worked in the shop here get that done. After Spring release, I will work on a larger oval and a twin 53mm for those who do not have a kegger opened up to the mono blade pattern. I can then also look at the v-10 and 4.0 Jeeps. But the spring plans are to start producing a new carbon fiber intake manifold printed and a new valve cover design with a removable top for super easy valve adjustments. A redesigned timing cover and carbon fiber oil pan round out the list. So as you can see, I have a nice schedule ahead of me for 2020. Stay tuned (get it?) and check back often!

2 Comments

Donald Helms

12/22/2019 02:45:08 pm

Marty, I've been following you for a while and think you have a really cool thing here. I have a 97 Ext.Cab Long Bed 4WD with close to 300K on the clock .I ordered this truck new and to date it has a dash and everything still works, If I have something go InOp I fix it. I use my truck to haul Giant Scale RC Jets and Fixed Wing War Birds all up and down the East Coast. I also do a bunch of 3DP of Cockpit and other scale items for my airframes so seeing what you are doing with the TBs makes me appreciate what you are putting out even more. So keep up the Outstanding work and have a Merry Christmas..

Reply

William Dame

12/22/2019 03:01:21 pm

I found this group just browsing through Facebook 1 day and since then I have been glued to everything you are building and customizing Marty. I appreciate every effort and everything you share with us about all these horsepower gains and I cant wait to get my hands on a Fabricated kegger and throttle body. I will also be able to be a perfect tester here on the east coast in new Jersey on my 99 Durango on 40s . Thank you Marty and the whole Utawesome performance shop

Reply

Leave a Reply. |

Marty FletcherHands on engine builder and tuner for Dodge since 1993. Archives

July 2023

Categories |