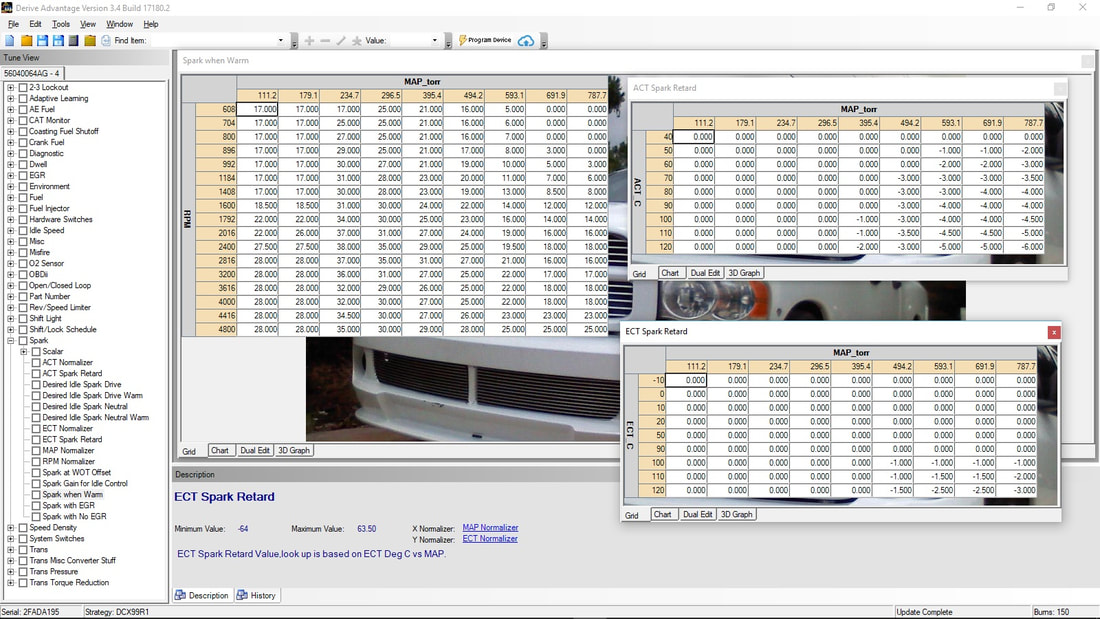

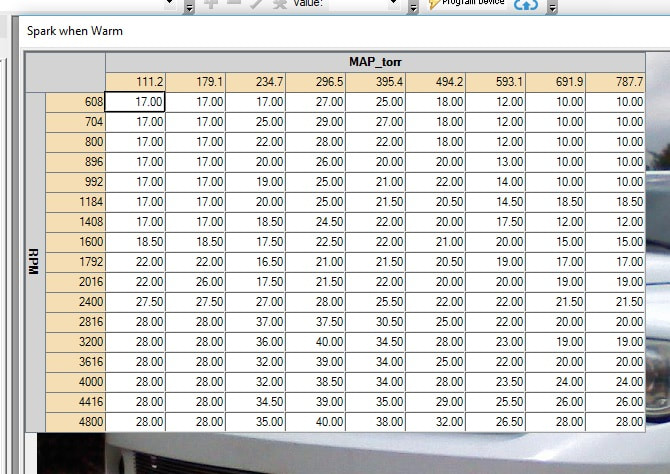

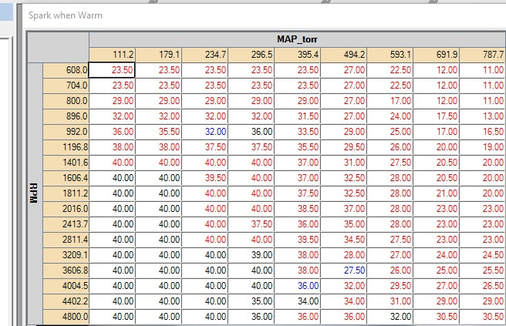

Superchips 93 Octane Spark Curve Superchips 93 Octane Spark Curve You can see that long gone are the days of having your spark distributor setup on the old Sun Machine. You would otherwise order a weight and spring kit for your distributor to dial in your spark curve. The weights were centrifugal and either made your timing come in faster or late. The amount could be limited also. (Ironic, I am speaking as if we do not do this anymore, yet we do.) With the advent of engine controllers, as you can see from Dodge Ram spark curve above, it is all done on a programmed grid. The Sun Machine and weight kit is now a laptop. Now different software will report your engine load (vacuum or lack of) in different ways. Why we can't just say inches of vac and zero vacuum is the same argument why us 'Muricans use standard wrenches compared to metric-pointless. Before OBD2 was released in 1996, all 1992-1995s were accessed by the OTC tool DRB-2. After that the DRB-3 was the tool. But when the fuel industry began diluting our fuel quality, many Chrysler vehicles with stock parts such as 195 and 205 thermostats, experienced spark knock. So when the customers brought in the vehicles to the dealer, one of the updates to cure spark knock, was to access the spark adjustment screen on the DRB-2 and pull timing out in 2 degrees increments. This was a global change on the spark table, not just a specific area. One of my good friends who was deep years ago in the Viper development program told me about a glitch in the DRB-2 that allowed us to actually advance that timing. Simply access the Spark Adjust screen, toggle the up and down buttons fast, and the global will jump and add 20 degrees increasing the idle instantly, and then you backed it down to a positive number such as +6. That little trick allowed us to pick up 20-30tq on a OBD1 controlled truck with no other mods. Worked really great on the 4 cylinder Wranglers with factory 4.10 gears which I raced in Albuquerque at 9 mile hill decades ago. So when the 1996 OBD2 trucks came out, the DRB-3 would reflash to a completely different timing table with changes in certain areas. I verified this with a simple scanner log of before and after in '96. Further verification was the main internet forum then everyone Dodge Truck related used, called The Dakota Mailing List by a great friend, Jon Steiger. Everyone was complaining their trucks was now sluggish and 2-3 tenths slower at the track. Well, when you go from 24 degrees timing to 16-18 at WOT, that is the result. So as I typed my scanner log findings to the group, I was watching Star Wars and at that moment, Luke had just destroyed the Death Star-hmm... So I coined it the Death Flash...true story, check the old Fredu University archives... Back on topic (stay on target Luke), wide open throttle (wot) is listed on SCT's view above as 787 torr, and 30 inches of high vacuum (decel), is 110 Torr. RPM is listed on the left side idle to 4800. Anything past 4800 in those cells, is simply used from there on. In the case above, 787 Torr WOT at 4800 commands 25 degrees spark. So 5500rpm will be the same. We now can rescale that to any rpm and adjust that specific area. Now when the trucks start to increase coolant temps, you can see timing is pulled out from your CTS sensor, especially when truly overheated to protect piston and head gasket failure. The same is said for you Air Inlet Temps via the IAT sensor in your hot aluminum manifold. In the old days, we would freeze the sensor before a pass at the track to get our max commanded timing, then relocated it to a cooler position than the 180-200 degree Beer Keg Intake Manifold. So as you can see with the completely stock Dodge table above even though we are commanding 25 degrees at WOT, with a bad coolant or IAT sensor, you could see an actual total timing of 16 degrees timing. That is why the very first mod was to relocate the IAT to a cooler area and add a 180 thermostat from the 195. When Mopar Performance released the Performance PCMs, they were an excellent improvement to leaning out an already fat fuel curve and weak spark advance curve. You can easily see the spark change in the second graph above from Mopar Performance. On 97 and later Mopar also turned off the torque management for even better tire frying launches. So when your HP Tuners, SCT or Diablo custom tuner is writing a custom tune for you involving spark, he or she is modifying that table and flashing the vehicle with it. Based upon your combo and octane, he is writing that table specific to your combo. Companies like Superchips, used the chassis dyno to come up with the best combo back then which actually bested the Mopar Calibration. You can see the 93 octane Superchips curve to the left. All together, they defeated the Death Flash~ although not with a joyous celebration on the Moon of Endor, we all rejoiced at tracks and dirt trails worldwide. Happy Thanksgiving from the Rusty Ram Mafia.

1 Comment

Tony

8/3/2020 11:24:34 am

So little ignition at full throttle !! I run the aftermarket ecu and have had the mp table as a starting point. I have been able to increase ignition significantly more than what mp and SC have there without any ping and the engine seems to like it. Jeep 5.2l engine manual transmission. Not driven in a dyno and wondering if I have more ignition than needed? Tips on what a modern safe table looks like.

Reply

Leave a Reply. |

Marty FletcherHands on engine builder and tuner for Dodge since 1993. Archives

July 2023

Categories |