|

You are the target. Not just the target of this article, but the target of big oil industries looking to take your hard earned cash from your account. Are you paying higher fuel costs each week and looking for any relief? If you happen to own any 1992-2003 Dodge Trucks or Jeeps that run the 3.9 V6, 5.2 V8 or 5.9 V8, then you know that gas mileage is terrible to start with. On top of that, you seem to have been adding more oil to the engine lately than normal. If that is you, then here is a modification you may be interested in performing or having a mechanic perform for you. If you are not interested in saving money then do not read on…

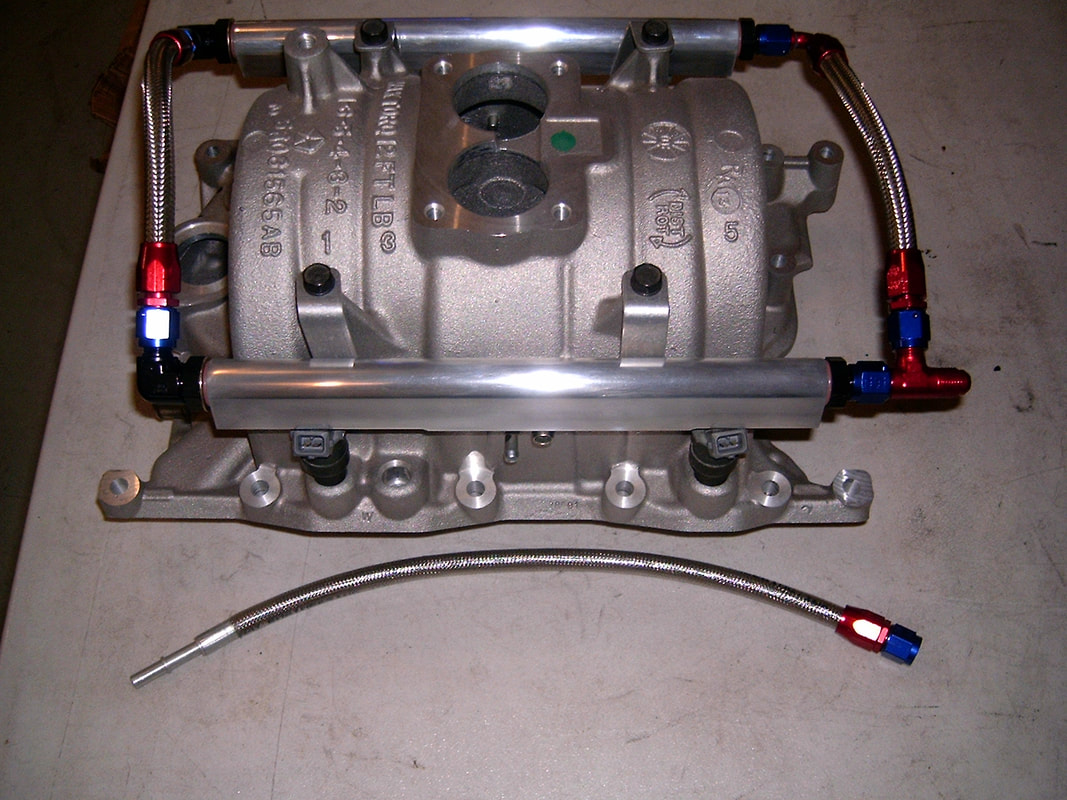

The Dodge/Jeep Magnum engine family consisting of the 3.9 V6 through the 5.9 V8 use a cast aluminum intake manifold that are the same. The only difference in the V6 version compared to the V8 is that 2 runners are missing from the smaller intake. Everything else in the design is identical. When Dodge designed the manifold, the casting factory used a mold that required the use of the plenum belly pan gasket and plate on the bottom side of the intake. As miles go by, this belly pan gasket begins to leak and eventually blows out. What that does is suck hot engine oil inside your intake manifold that is only supposed to be moving air through it. The symptoms are oil burning blue out the rear of the vehicle, high oil consumption, erratic idling due to the vacuum loss and low power with excessive fuel costs. There are literally 600, 000+ documented service tickets across the fleets that have been repaired and completed. That is just dealerships in the system; this does not include independent shops or other make dealerships. The repair has always been the same; the technician removes the intake manifold, cleans it, installs a new belly pan gasket along with new intake manifold gaskets, tops off the coolant and sends you on for 3 hours labor charges plus parts. Now depending upon your driving and use, this usually last for about 30,000 miles. Some have gone much further never wondering why they have all these symptoms of excessive fuel and oil. If you do not care, then you are not supposed to be reading this article as explained in the beginning. But continuing, along with this normal repair, there are a few additional things that can be done to keep you from ever performing or paying for that job again. If you are the ‘do it yourself’ mechanic, feel free to tackle this with minimal cost. If you are not, then you will need to find a competent mechanic who will do this for you. The 15 bolts that retain the belly plate to the lower intake manifold unfortunately are too long. Before they can seal and crush the gasket to the intake lowers, they bottom out. This explains WHY the repaired gaskets blow out later on. Simply purchasing ¼” lock washers and flat washers at your local home improvement or hardware store will solve this. Second, if your new belly pan gasket is made of paper or the premium steel one from the dealership, you still need a thin coat of sealant (RTV Black) on both sides of the gasket. Third, you will need to purchase Red LocTite to ensure the 15 bolts will not come loose- even though you have lock washers installed. These simple cheap steps will cost no more than $15 compared to the 3 hours labor bill every 2 years. Three simple and cheap yet effective steps to stop the oil burning in the intake manifold that should always be done to effectively end the blown gasket problem and issues it causes. So how do we take this one more step to get performance and additional miles per gallon? Simple, with two additional modifications, you will see 2-3 more miles per gallon on average. The cost of these two modifications will average around $60. You will make that back in the first month of driving due to fuel savings costs. For the Jeeps that are required to run premium fuel due to the higher spark advance in the engines computer, you will be able to run 86/87 low octanes. The cost of 93 octane to 86/87 is a huge fuel savings. The past solution was to run a lower temperature thermostat from 195 degrees to a 180 degrees thermostat. This lowering of the intake manifold temps allowed lower octane to be used, but in the winter is not warm enough to take the chill off of the driver. With these two modifications, you will be able to run a hotter 195 degree thermostat and lower octane fuel. The first modification is an oil catch can that prevents oil from being pulled into the intake via the PCV valve. There are many nice polished, anodized and billet catch cans available from Amazon online that can be delivered to your door for $30. The installation is simple- the PCV vacuum line that originally connected the valve cover to the intake manifold, now routes to the oil catch can, then the outlet of the can connects to the intake manifold. This traps any oil that is pushed out of your PCV valve and prevents it from being introduced into the intake manifold (burning oil). The can has a small drain on the bottom and sight gauge to tell you if it is filling up. A new PCV valve $10 is worth adding at this time also. The final modification is a trick that automobile manufactures used to employ, but no longer use. It was called the valley pan gasket. You see, underneath the intake, that belly pan has hot engine oil splashed on it when running. This heats up the lower belly pan to 180-200 degrees and higher. By preventing this issue, the manifold, even running a 195 degree thermostat, will see temps in the 140-150 range. Much lower than 180-200 temps that splashed your newly replaced plenum gasket and pan. The valley pan gasket shields the oil from hitting the intake and allows dense cooler incoming air to feed the cylinder heads. That in turn makes more horsepower and torque. Since no one makes a valley pan gasket for the Magnum series engines, you have to be creative. The easy solution is to purchase a Valley Pan Intake gasket from NAPA for a 1970-383cubic inch big block Dodge or Chrysler V8. This will run about $28. With the intake manifold removed, trim the sheet metal gasket to fit in the valley. When trimming the sides of the gasket, you will want to keep the edges of the pan as close to the cylinder head as possible blocking as much oil splash as possible. To clear the intake manifolds lower plenum corners, you will need to cut a 1” square from each corner. Using the 3 factory bolts that hold down your lifter retainers (you will see them), align and drill three holes to bolt the pan to them. Now simply take a sharp punch and punch a small hole in the middle rear of the pan for oil to drain out if it makes its way above the pan. Install fresh intake manifold gaskets and then install the manifold directly over it as normal. Top off the coolant, and fill her up with fresh 87 Octane fuel. The addition of this valley pan shield and catch can has allowed dyno testing of performance engines to use 87 octane as compared to 91/93 premium. Although you may not be building a performance engine, you WILL benefit from using cheaper 87 octane fuel and not adding a quart of oil every week to your engine. That is money and savings that will stop the leaks from your intake manifold- and your wallet!

3 Comments

Roger Ford

11/6/2018 05:50:01 pm

Great article and awesome tips I really look forward to reading them.

Reply

James Hall

9/18/2019 06:32:36 am

I came across this idea several years ago myself. I'm a 30+ yr experience tech and I think about how things and devise solutions. I also realized that the bolts were the problem. My solution was to utilize the washers .used a wide flat washer to spread the load and bought thick white gasket paper and cut my new gasket. I'm 3 years in and no issues. I had thought of a belly pan as I knew it would help temps. Cool dense charge. Now Thanks to you guys, I know what to do. 383 gasket. Do I trim away the intake port area or have it as the intake gasket like the 383 did?

Reply

David Lund

1/19/2021 08:33:16 am

Look at one of the pictures and you’ll see what’s cut away.

Reply

Leave a Reply. |

Marty FletcherHands on engine builder and tuner for Dodge since 1993. Archives

July 2023

Categories |